How to use: Build visual.

How to Create and Read an I-MR Control Chart

The steps involved . We had seen mainly 03 charts that are used in the case of Continuous data.

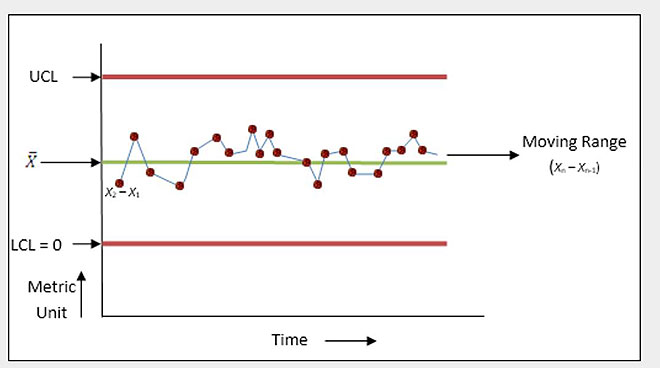

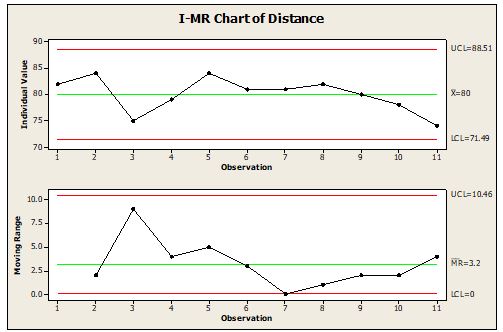

plottedNo single value should appear more than 25% of the timeI-MR Chart• Lo.I-MR charts are valuable tools for monitoring process stability, especially when data is collected one sample at a time. Within Minitab, control charts are created by using the “Stat” pull down menu, then selecting “Control Charts.An MR-chart is a type of control chart used to process variability (as the moving range of successive observations) when measuring individuals at regular intervals from a process. For example, you can use a control chart to verify that the process was stable. Let’s say you work for a chemical company, and you need to assess whether the pH value for a custom solution is within acceptable . If you do not specify a historical value for the process mean, Minitab uses the mean of the .In this vignette I have demonstrated the use of the qicharts package to create control charts for measure and count data. Each data point, x i, is an observation.

How to Create a Control Chart in Power BI

Make sure to use the actual dates instead of the Date Hierarchy. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process.Control limits on the I-MR are derived from the change in range (moving range) The control limits on the Xbar-R chart are derived from the average rangeIf the Range chart is out of contro.In this video I will be talking about control charts including X-bar chart, R-chart and I-MR chart.

I-MR Control Chart

The following elements make up the XmR chart: MR (moving range) – difference to previous value. Analyze > Quality and Process > Control Chart Builder; Analyze > Quality and Process > Control Chart > IMR Control Chart . Step-by-step guide. Control charts are a valuable tool in data analysis, providing a visual representation of how a process changes over time. Click on the “I-MR Options. In the XmR chart, each data point consists of one observation of continuous data. Create a line chart with the measures: Once you created these measures, create a line chart. Then we drag and drop Hour over the range chart to create an X-bar and R chart for Thickness.” Within the Control Charts window, select “Variable Charts for Individuals” and then finally select “I-MR.The XmR chart is a great statistical process control (SPC) tool that can help you answer this question, reduce waste, and increase productivity. Then use a run chart to identify patterns that may not be detected in a . For that, seek .

Creating an I and MR Chart Using the Control Chart Builder

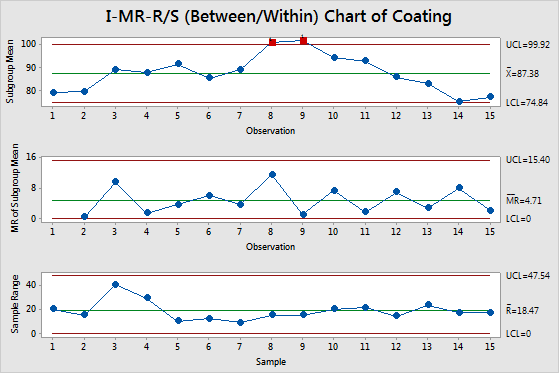

Together with my vignettes on run charts it forms a reference on the typical day-to-day use of the package.How Does I-MR Chart Work? As mentioned earlier, there are two charts for I-MR, Individual Chart and Moving Range Chart – let’s discuss it one-by-one and see how it compliments each other to interpret the process .Creating an I-MR control chart. That creates an I-MR . Use I-MR Chart to monitor the mean and variation of your process when you have continuous data that are individual observations not in subgroups. My favorite example of applying the lessons of quality improvement in business to your personal life involves Bill Howell, who applied his Six Sigma expertise to the . We drag the column Thickness into the Y drop zone.How to Create an I-MR-R Chart Using QI Macros Add-in for Excel: Select two or more columns of data. To conduct a capability analysis, we right-click over the control chart, and select Limits and then Add . nsigma — The number of sigma multiples from the center line to a control limit.

Conducting a Capability Analysis Using the Control Chart Builder

Select the Date for the axis.66 is sometimes used to calculate XmR chart limits. When data are individual observations, it is not possible to use the standard deviation or range of subgroups to assess the variability and instead the moving range is . The Control Chart Builder has a drag-and-drop interface for creating control charts, much like the Graph Builder. [1] The chart is necessary in the following situations: [2] : 231.Shewhart individuals control chart. Using the 2,66 constant Control Limits = X ± 2. We’ll cover the concepts behind XmR charting and explain the XmR control constant with some super simple R code.

How to make Shewhart control charts in R

Look for out of control points.A control chart is a statistical tool that can help users identify variation and use that knowledge to inform the development of changes for improvement.

Variables Control Charts

In this tutorial, we will explore the importance of using control charts .

I-MR-R Chart in Excel

Recall that, in this scenario, an improvement team is tasked with improving Yield, and that Yield . We drag the column MFI into the Y drop zone. Individuals-Control-Chart image from Smarter Solutions. The D4 constant is a function of d2 and d3: D4 = 1 + 3 (d3 / d2) = 3.

Here you can easily create control charts for your data online.

Individuals

Go to Stat > Control Charts > Variables Charts for Individuals > I & MR Chart.Variables Control Charts – I/MR Charts Create Individuals and Moving Range control charts to monitor the performance of a continuous variable over time.A few years later, Mr.Control Chart Examples.This is the p parameter for p and np charts, the mean defects per unit for u and c charts, and the normal mu parameter for other charts.

Medians and the Individuals Control Chart

Autor: Doug H

Control Chart

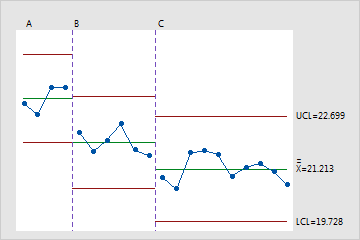

Control limits – upper and lower limits between where 95-99% of values sit (calculated from the centre line and MR average .Select and use the following control charts in various situations: X¯ – R, X¯ – s, individual and moving range (ImR), attribute charts (p, np, c, u), short-run SPC and moving .The overall average ( X) and the average moving range ( R) are then calculated using the following formulas: X = S X/k.Now, let’s start with the creation and interpretation of control charts from this video.I-MR Charts can be created in Microsoft Excel or in Minitab. I chart An I-chart is a type of control chart used to monitor the process . The values change from 2 to 3 to indicate the beginning of stage 3.Video ansehen9:55A Control Chart is the go to Six Sigma chart that you’ll probably see if you’re in working in a manufacturing operations role or taking business operations c.We can check our results by using the original data to create an I-MR chart. By using our I-MR Control Chart Tool, you can quickly and easily generate I-MR charts to . Under When to start a new stage, select With each new value.In Define stages (historical groups) with this variable, enter the column that identifies the stages. A control chart helps identify any patterns or anomalies in a dataset, allowing for effective decision-making based on the trends observed.

I-MR Control Chart Analyzer

Open the sample data, DetergentpH.The constant 2. “One of the worst parts, honestly, was that Bob’s departure would further complicate the tangled web of . A quality engineer monitors the manufacture of liquid detergent and wants to assess whether the process is in control.

We select Control Chart Builder from the Analyze menu under Quality and Process. Finally, to create an r chart we repeat the process above except now we will specify that we want an r chart instead of an x-bar chart. Select Raw Data: 2.

Shewhart individuals control chart

Individuals with Moving Range (I-MR) control charts

It was not my intention to go deep into the theoretical basis of run and control charts. For example, a hospital administrator wants to . The engineer creates an I-MR chart to monitor the detergent process. An individual and moving range chart is .Create an R chart. Actuals: this field contains your measurements.Example of I-MR Chart. The constant takes into account the 3 used to calculate the upper and lower control limit.MR chart An MR-chart is a type of control chart used to process variability (as the moving range of successive observations) when measuring individuals at regular intervals from a process. Control of the process average or mean is usually done wi.Creating the I-MR Chart.

Methods and Formulas: How Are I-MR Chart Control Limits

parent — The handle of the axes to receive the control chart plot. It can be easily created in either Microsoft Excel or Minitab. Plotted points; Center line ; Control limits; Plotted points. LCLx = X – 2.An I-chart is a type of control chart used to monitor the process mean when measuring individuals at regular intervals from a process.The I-MR chart (Individuals and Moving Range) is the variable data control chart to be used when each item is processed uniquely and therefore a subgroup sample size of one is appropriate. Note that the color scheme remains altered since we changed qcc.The Control Chart Analysis Tool offers a robust method for monitoring and analyzing the stability and performance of processes over time. We enter the data column in Variables, and then click I-MR Options and choose the Storage tab; here .” In the Minitab I-MR Chart panel, you will need to . In this Introduction to .The best practice for creating a control chart for continuous data is to collect the data using rational subgrouping; however, many processes make rational .’s mother split up. xbar_chart2 <- qcc (data = chartdata2, type = R, sizes = 5, title = Sample R Chart Title, digits = 2, plot . In the example below, the values in the Stage column change from 1 to 2 to indicate the beginning of stage 2. The available fields are: Axis: here you add the category you want to use as your x-axis. Special causes must be eliminated.Shewhart variables control charts; I-MR chart An I-MR chart is a combination of control charts used to monitor the process variability (as the moving range between successive observations) and average (as the mean) when measuring individuals at regular intervals from a process. To use the Control Chart XmR, you need to have a dataset with at least a date-field and a numeric field. The center line represents the process mean, μ.Lower Control Limit (LCL) = AVERAGE CASES – [STDEV]*3.How to Create an I & MR Chart in Minitab 1. R = S R/ (k-1) where k = number of samples.Create Individuals and Moving Range control charts to monitor the performance of a continuous variable over time.An I-MR chart is a combination of control charts used to monitor the process variability (as the moving range between successive observations) and average (as the mean) when . In this video, we show how to create an I and MR chart using the Control Chart Builder with the White Polymer Crisis Team data.Watch this video to learn how to create an I-MR control chart in Minitab Statistical Software. Select a cell in the dataset.Constructing and Interpreting I-MR Charts.

I-MR Control Chart: Detailed illustration with Practical Example

I chart > Shewhart variables control charts

Centre line – mean of actual values (recalculated to account for step changes) MR average – mean of moving range.Welcome to Turnitin Guides. Click on the QI Macros menu and select Control Charts (SPC) > . The engineer measures the pH of 25 consecutive batches of detergent.

An individual and moving range, or I and MR, chart is used to monitor individual measurements over time.

Learn more about Minitab . Welcome to Turnitin’s new website for guidance! In 2024, we migrated our comprehensive library of guidance from https://help.First, we select Control Chart Builder from the Analyze menu under Quality and Process.We go ahead and construct an I and MR chart. Rooted in the principles of statistical . A run chart plots your process data in the order that they were collected.Use a Run chart to look for patterns or trends in your data that indicate the presence of special-cause variation.To start, they created a template for their data by selecting the “Control Charts” button in the SuperEasyStats Ribbon and then choosing “Individuals with Moving Range (I-MR) Chart”.In this video you’ll learn how to create an I‑MR Chart in Minitab Online as well as how to recalculate control limits once a change has been made to the process. Click OK again: . Drag LCL, UCL, and Average Cases into values. Select the method or formula of your choice. In statistical quality control, the individual/moving-range chart is a type of control chart used to monitor variables data from a business or industrial process for which it is impractical to use rational subgroups. You can download the data set used in this video from our data.

I-MR chart > Shewhart variables control charts

The following actions should give you a view of the main components of a control chart. Constructing accurate I-MR control charts is crucial for effective process monitoring and control. Lastly, we’ll cover how to make the XmR plot by hand, with base R code, . In this video, we show how to create an I and MR . Simply select whether you want to create a control chart for continuous or attributive data and then select the . Plot a Shewhart control chart for individual observations to determine if a process is in a state of statistical control.66 = 3 / d2 = 3 / 1. Control charts are most frequently used for quality improvement and assurance, but they can be applied to almost any situation that involves variation. Now you can calculate the upper control limit (UCLx) and lower control limit (LCLx) for the X chart as follows: UCLx = X + 2.XmR chart, also called an I-MR chart, is a combination of two charts (Individual and Moving Range) to track the process variability based on the samples taken from a process over a period of time. Default is to create axes in a new figure .

- Foreign service academy: federal foreign office diplomacy

- Warum gute hausverwalter es nicht immer leicht haben!, was verdient ein weg verwalter

- Weihnachtskarten ideenreise – weihnachtskarten ideen geschäftlich

- Billboard top 100 hits of 1967 | top 100 pop songs 1967

- Kosten für den einbruchschutz sind überschaubar, stiftung warentest einbruchschutz 2022

- Frühe hilfen in der städteregion aachen, frühförderung lebenshilfe aachen