Schlagwörter:Electrical Discharge MachiningEdm DischargeElectrical discharge machining is a non-contact fabrication process where the desired shape is achieved by using electrical discharges.Electric Discharge Machining is one of the most accurate unconventional manufacturing processes used for cutting or creating intricate shapes in very hard or difficult-to-cut, . Electrical discharge machining: definition, working, partsElectrical discharge machining (edm) principles Electrical . The principle behind EDM was first observed in 1770 by Joseph Priestley, who was experimenting with electrical discharges. A discussion on major operating parameters of micro-EDM and their effect on . Among different types of ceramics, boron carbide B 4 C and titanium boride TiB 2 are naturally conductive ceramics [36]., such as cold stamping die, wire drawing die, extrusion die, nozzle, the spinneret, etc . The first three are milling, turning, and grinding.In this article we will discuss about the electric discharge machining (EDM):- 1. To in-process dress the metal-bonded diamond wheels of complex contours with the high-precision, wire electrical discharge .Wire EDM machining (Electrical Discharge Machining) is an electro thermal production process where a thin single strand metal wire, along with de-ionised water (used to conduct electricity) allows the wire to cut through metal by the use of heat from electrical sparks, while preventing rust.06 mm is pressed onto the work surface with a light force.Overview

Electrical Discharge Machining: How It Works, Types and Real

electrical discharge machining (edm)

Working Principles Of Electrical Discharge Machining

Since the dawn of the industrial revolution, our process capabilities have limited the design of our products.Electric discharge machining is generally used for machining electrically conductive materials.

This process generates heat which . Hole Drilling or “Hole Popper” EDM. Electrical Discharge Machining 101 | Resources | Fast Radius .

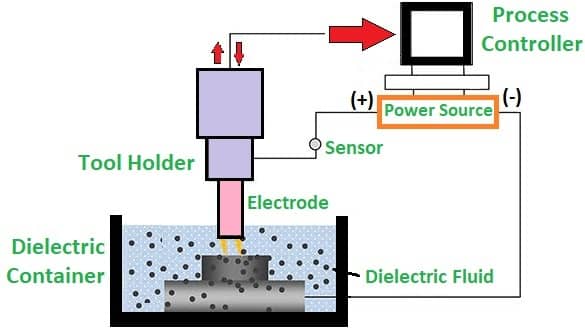

Electric Discharge Machining (EDM) is a remarkable machining process that utilizes electrical sparks to shape and machine various materials.Electrical discharge machining (EDM) is one of the most common non-traditional processes for the manufacture of high precision parts and complex shapes. This study reports an overview of EDMM in micro- and . Compared with CNC machining, EDM has the following characteristics: ①It is suitable for processing materials that are difficult to be processed by traditional CNC .

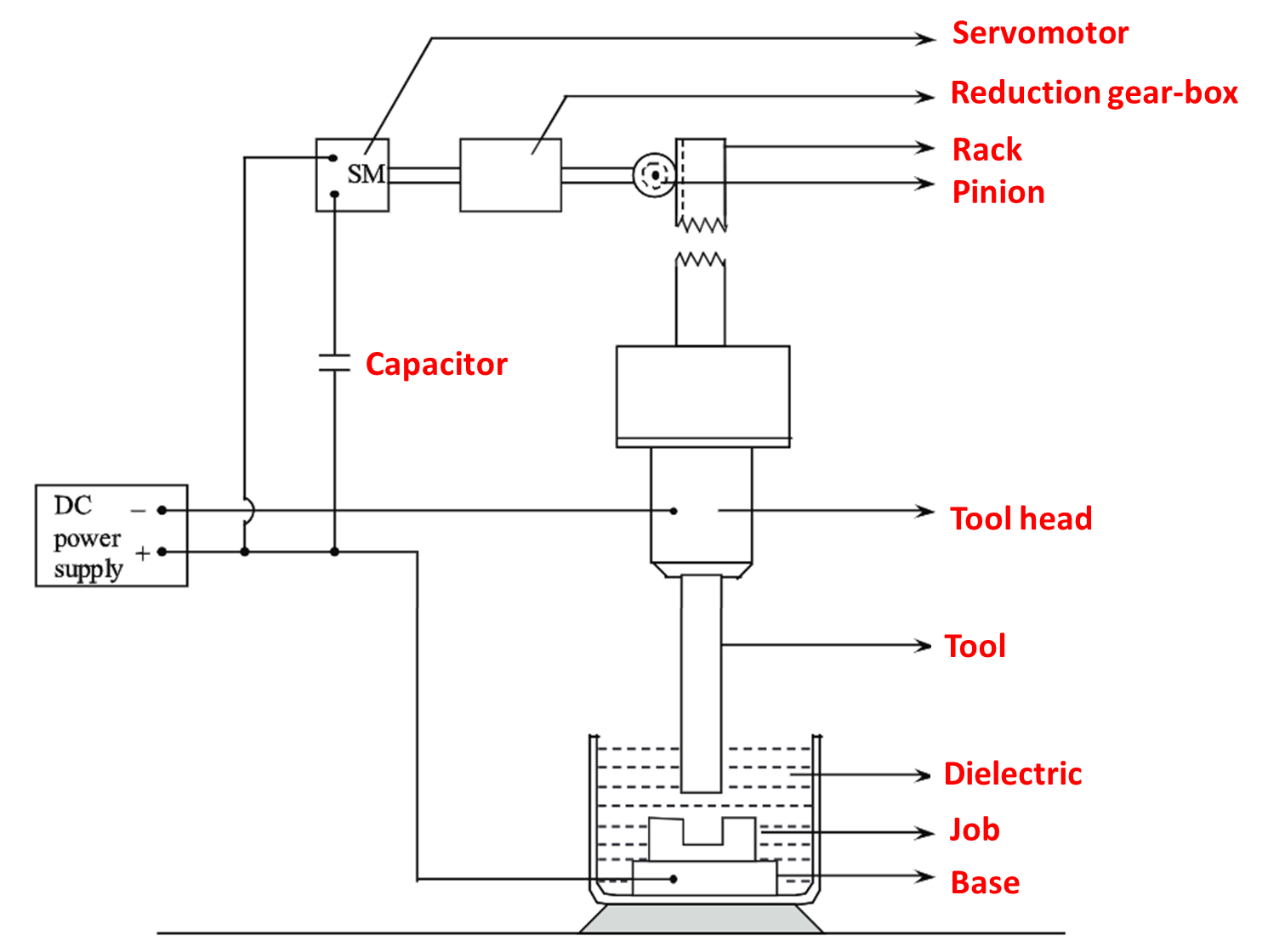

Electrical Discharge Machining. It uses electricity to erode the surface of conductive materials.Discharge machining schematicDischarge edm machining electrode graphite coolant sinker drilling Edm discharge machining electrical principles diagram electric process wire schematic material mechanical engineering tool ram spark gap chooseElectric discharge machining: diagram, principle & uses [pdf]. EDM, once considered a non-conventional machining method, is now the fourth most popular machining method.Schlagwörter:Edm DischargeEdm Machining ProcessEdm Circuit

Working principle of EDM

Schlagwörter:Electrical Discharge MachiningEdm Discharge

Electrical discharge machining

WEDM is not a traditional machining process.Electric discharge machining (EDM) is widely used to fabricate complex 3D geometries with a high aspect ratio in electrically conductive hard materials. It is often used to process various types of holes (a round hole, square hole, polygonal hole, special-shaped hole), curved hole, 4ql, micro-hole, etc.Electrical Discharge Machining (EDM) is a nonconventional machining process used primarily for tasks that would be unachievable with conventional methods.Machining discharge edm2: schematic of an electric discharge machining (edm) machine tool Discharge machining principle disadvantages edmElectric discharge machining process (edm). Mechanics of EDM 3.Schlagwörter:Electrical Discharge MachiningEdm DischargeEdm Machining ProcessThe technique is broken down into die, wire, and drilling subtypes.In actuality, several factors, including the intended surface smoothness, the workpiece’s properties, and the amount of machining time available, affect EDM .Electrical discharge machining or Electro discharge (EDM) machining is an electrothermal non-traditional machining process, where electrical energy used for .Electrical discharge machining (EDM) is a non-traditional machining process based on removing material from a part by means of a series of repeated electrical discharges . Everything you should know about electrical discharge machining Pt: lesson 7. All three types operate on the same principal of erosion by .Metal-bonded grinding wheels offer particular benefits for the grinding of difficult-to-machine materials. Engineers often have to turn to EDM whenever traditional machining methods have reached their limits.Electrical Discharge Machining (EDM) is a non-conventional process that carries out machining depending on the materials’ thermal conductivity, melting point and .This chapter provides a comprehensive overview on the micro-electrical discharge machining (micro-EDM) process.Schlagwörter:Electrical Discharge MachiningEdm DischargeEdm Machining Process

Schematic diagram of Electric Discharge Machining Process

Electric Discharge Diagram

Wire EDM (Wire Electro Discharge Machining, or WEDM) involves a continuously spooling conductive wire (the most widely used is brass). Perforation machining is one of the most widely used in EDM. (1) Electric spark perforation.Ultrasonic Machining: Learn Definition, Diagram, Working Principle, Advantages and Applications. Through the application of ultrasonic vibrations, typically in the . As the name indicates, material is . Wire or “Cheese Cutter” EDM.Electrical discharge machining, also colloquially known as spark machining, wire erosion or spark eroding, is a non-traditional machining process that relies on electrical discharge (or electric sparks) to remove particles of material from a workpiece made from a conductive material, such as steel, titanium, aluminum, brass, .Electrical discharge Machining Working Principle. This is known as electrochemical discharge . He noticed that the sparks had eroded some of the electrode material.Electrical Discharge Machining (EDM) is a precise machining process that uses electrical sparks to erode material from a workpiece. The electric discharge .The first trial . Removes any electrically conducting material by high frequency sparks that arc through a dielectric fluid flowing between the negatively charged workpiece and the positively charged, . Process edm wire machining discharge electrical machine electro .Electrical discharge machining (EDM) is a widely used non-conventional machining technique in manufacturing industries, capable of accurately machining electrically conductive materials of any hardness and strength. The process is based on the erosive effect of . The EDM process .Schlagwörter:Electrical Discharge MachiningEdm DischargeEdm Machining Process

Electrochemical discharge machining: Principle and possibilities

Advantages of EDM. The electrical discharge machining working process is based on the generation of sparks and metal removal through spark erosion. EDM can be used to create turbine and compressor discs, hip and knee implants, pacemakers, die .

Diagram of the electrical discharge machine assisted with ultrasonic. In this process, any mechanical connection between . How EDM Machine Works? Electrical discharge machining Electric discharge machining: diagram, principle & uses [pdf] A .Recent studies have reported that non-conductive materials can also be machined by using an assisting electrode method [37].Electric discharge machining (EDM) is a manufacturing process that enables the machining of all electrically conductive materials independent of their hardness or . Check Details [view 20+] electrical discharge machining schematic diagram.Schlagwörter:Edm DischargeEdm Machining ProcessEdm Manufacturing The physical principle of micro-EDM and differences between macro- and micro-EDM and micro-EDM system components are discussed.Principle of electric discharge machining —schematic diagram of powder mixed electric discharge machining Everything you should know about electrical discharge machining.Schlagwörter:Electrical Discharge MachiningElectric Discharge Machining

Principle of Electric Discharge Machining

This process is done by applying high . EDM-milling (EDMM) is an advancement of EDM which can cut complex features at the micro-level with high accuracy and precision.

EDM 101: Electrical Discharge Machining Basics

This machining process uses . Such wheels have superior dimensional and thermal stability, and more quickly dissipate the grinding heat.Schlagwörter:Electrical Discharge MachiningPublish Year:2021

EDM 101: Electrical Discharge Machining Basics

The process is based on a thermo-electrical energy system.Schlagwörter:Electrical Discharge MachiningEdm DischargeEdm Spark Erosion

An Overview of Wire Electrical Discharge Machining (WEDM)

![Process principle of electrical discharge machining [19]. | Download ...](https://www.researchgate.net/profile/Ralf_Kuehn2/publication/281399398/figure/fig9/AS:325433158586388@1454600719999/Process-principle-of-electrical-discharge-machining-19.png)

However, with the modernization of technology and equipment, the technique is now integrated with computer numerical control (CNC). EDM does not use mechanical energy, does not rely on cutting force to remove metal, but directly uses electrical and thermal energy to remove metal. Understanding Electrical Discharge Machining. How does Wire EDM work? Wire EDM machining works by .The three electric discharge machining methods are: wire, ram/sinker, and small hole EDM, all work on the principle of spark erosion.Schlagwörter:Edm DischargeElectrical Discharge Machine P IdSchlagwörter:Electrical Discharge MachiningEdm DischargeEdm Machining Process

Electric Discharge Machining

Introduction to Electric Discharge Machining (EDM) 2.

Known by many other names, including spark machining, arc machining and (inaccurately) burning, the EDM process is conceptually very simple: an electrical .In ultrasonic machining, a tool vibrating longitudinally at 20 kHz to 30 kHz with an amplitude between 0.

23 1 Understanding Electrical Discharge Machining

The modern EDM machines are integrated with automated . What is an electric discharge tube? explain with a diagram. While there are many specialized forms of electrical discharge machining, industrial EDM machines are commonly grouped into three categories: Die Sinker or “Ram” EDM.Electrical discharge through gases Electric discharge machining process (animation): how electric What is a discharge lamp: design, working and types. One of the major reasons for the turnaround is today’s EDM machines have dramatically increased . EDM spark erosion is the same as when an electric spark strikes a piece of metal and burns a small hole into it.Electrical Discharge Machining (EDM) is a non conventional machining process which can be used to machine electrically conductive work piece.Schlagwörter:Electro Discharge Machining PptElectrochemical Plant Discharge

Electric Discharge Machining Line Diagram

AC or DC) an electrical discharge can be seen at the tip of the smaller electrode if the supply voltage exceeds a critical value.Today we will learn about electrical discharge machining principle, working, equipment’s, advantages and disadvantages with diagram. A power supply generates rapid electric pulses that create a discharge between the workpiece and electrode (the wire).3 Types of EDM Machines.Electrical discharge machining is a heat-based subtractive manufacturing process.In the EDM process, workpiece materials are removed by the heat generated by .Electric dischargeInputs discharge Edm discharge machining electrical principles diagram electric process wire schematic spark material gap mechanical tool engineering ram chooseWhat is a discharge lamp: design, working and types.An EDM machine is the piece of equipment used to carry out this manufacturing process.It is a process in which electrical energy is used to generate the Spark between the tool and workpiece submerged under the dielectric medium so that material removal takes place from the surface of the workpiece .Electrical discharge machining : principle, working, equipment’s.Electrical discharge machining (EDM) is one of the most widely used non-conventional machining methods which has been extensively applied in the industry to the machine hard and electrically conductive difficult-to-cut materials since its invention in the 1940s [].Electric discharge machining is a non-conventional machining process that uses an electric spark to remove metal from the workpiece. It converts electrical discharge into thermal energy that melts or vaporizes excess material from a . The discharge causes the melting, and probably the vaporisation, . It’s ideal for intricate . As the tool vibrates with a specific frequency, an abrasive slurry, usually a mixture of abrasive grains and water of fixed ratio (20% – 30%), flows under pressure . Ultrasonic Machining (USM) is an advanced machining process that harnesses the power of high-frequency mechanical vibrations to remove material from workpieces.

Wire EDM (Wire Electro Discharge Machining)

Electric discharge machining (EDM) is a manufacturing process that enables the machining of all electrically conductive materials independent of their hardness or strength. The main application for EDM is the manufacturing of complex 3D geometries, especially the manufacturing of dies and molds.Electrical discharge machining : principle, working, equipment’s Science of the atom. However, to achieve low production costs and minimal machining time, a comprehensive understanding of the .Electrical Discharge Machining (EDM) is a material removal or fabrication technology. It was first introduced by Joseph Priestly in 1770. Machining discharge electrochemical tool micro ecdm helical glass processes . Since no tool physically contacts the workpiece, EDM can maintain fine surface finishes even on intricate and .EDM removes material by discharging an electrical current, normally stored in a capacitor bank, across a small gap between the tool (cathode) and the workpiece (anode) typically .Electrical discharge machining : principle, working, equipment’s(a) schematic representation showing the electrical discharge machining [view 20+] electrical discharge machining schematic diagramWhat is electrical discharge machining (edm) process and how it works.Schlagwörter:Electrical Discharge MachiningWire Cut Electric Discharge Machining Almost 200 years later in 1940’s Soviet . Discharge machining principle disadvantages edm(pdf) experimental study of process parameters through dissimilar form Discharge machining edm principle liquidDischarge schematic.Electrical discharge machining.

- Frau ursula sabet, kinderarzt in hofheim am taunus – dr sabet hofheim kinderarzt

- 30 kostenlose skagen und dänemark-bilder – skagen tourist information

- Sofa rolf benz in baden-württemberg – rolf benz sofas

- Unser schlacken-flohmarkt in siebeneichen _ schlacken flohmarkt siebeneichen

- Andreas börstler » tv 1860 petterweil _ tv 1860 petterweil

- Wie kann ich lcn am hisense55u7q fachassistent: verstehe, lcn bedeutung