Arguably, cutting tools fall here as well. Consolidate Assemblies . Adapted from [13].EOAT End-of-Arm Tooling Custom end-of-arm tooling for robots, also referred to as EOAT, is made specifically for applications like grabbing parts, welding painting, or sensing.EMI End Of ArM TOOlIng 216-535-4848 EOAT Engineers are available via phone, email, chat or video call.Custom End-of-Arm-Tools. Facility; Components; End-of-Arm Robotic Tooling; Gate Cutting; 3D Printing; About Us. Email: [email protected] 3D Printing for Automation.

How 3D Printed End of Arm Tooling Aids Automation

Anubis 3D is a leading Additive Manufacturer-3D printing service provider for rapid End of Arm Tooling EOAT and On-Demand industrial components either Prototypes or Low .

Funktionsmuster und Endbauteile – topeffizient direkt aus dem Drucker.

End-of-Arm Tooling (EOAT)

Deutsch

Why 3D Printing is the perfect way to create End-of-Arm Tooling

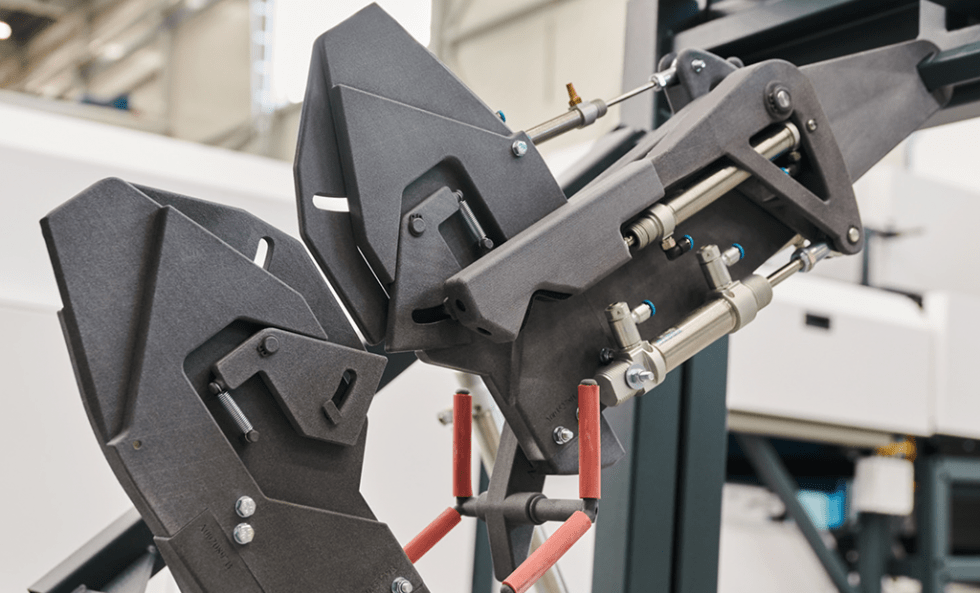

Our core competencies include mechatronic gripper parts, robot hands / End-of-Arm-Tools (EOAT) and automation systems. We use examples and case studies from BASF Forward AM. Custom-fit for your application: 3D-printed lightweight components or robot grippers made of fiber .

Transforming Robotic End of Arm Tooling with 3D Printing

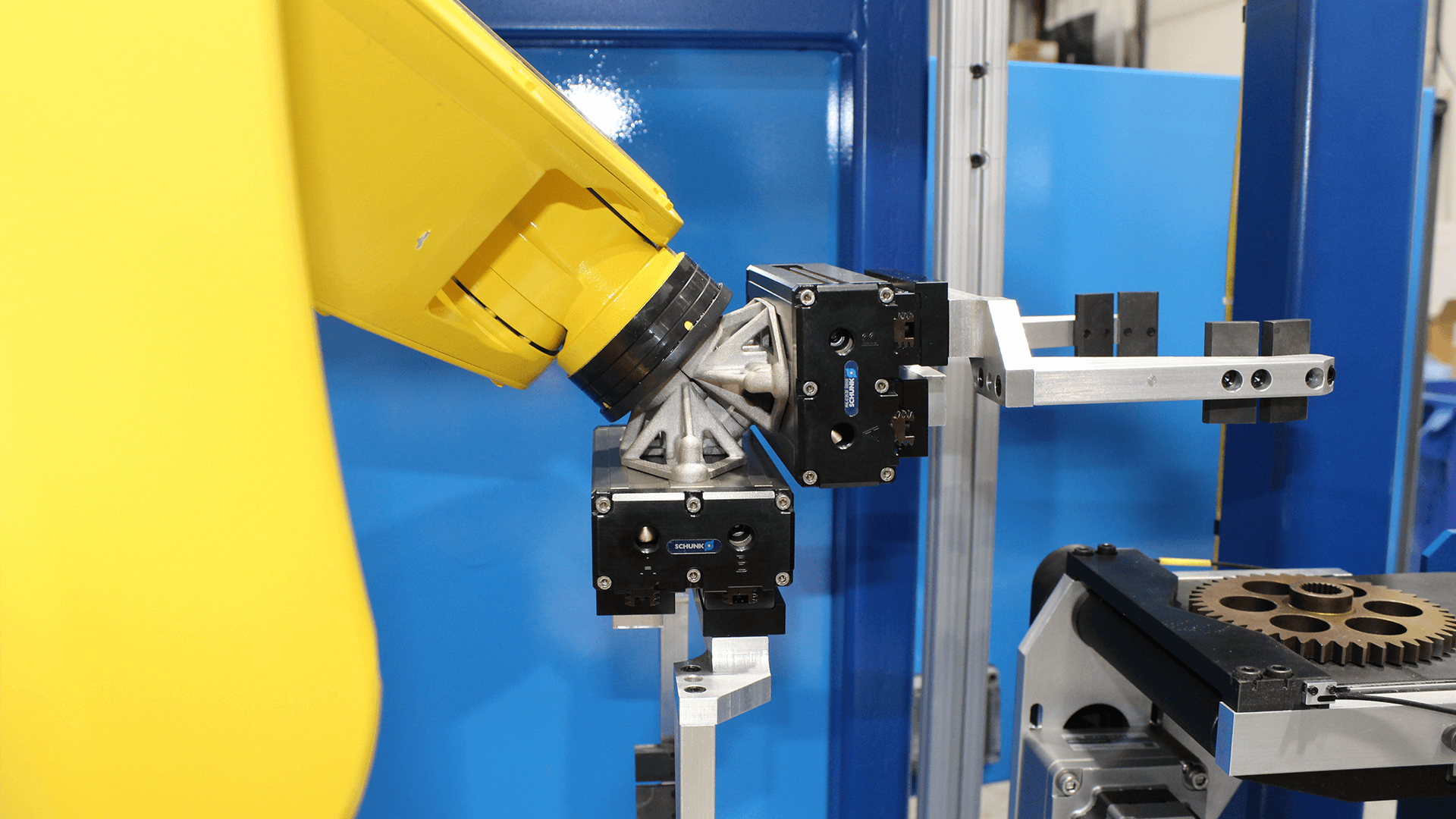

EOAT Components. Examples might include a manufacturing tool like a welding torch, a gripping or positioning mechanism or a computer vision system. For example, the welding torch on a robotic welding system. Build information Three full gripper sets were printed on the H350™ 3D printer within 9 hours and 24 minutes. The new end of arm tools can be catered to the individual machine’s design specifications while still holding their own to their predecessor’s. This gripper was created based off of a As a high-quality and practice-oriented modular system for automation, it offers greatest possible flexibility for gripper construction. (a) Robot Control Isolator.4cm3 for each assembled gripper. (b) FANUC Robotic Arm.End-of-arm tooling (EOAT) – the ‘hands’ at the end of industrial robot arms – should be lightweight and conformal to each unique part a robot manipulates.Robotic end-of-arm tooling stands as an essential component in industrial automation, revolutionizing how materials are handled, assembled, and processed.3D Print End of Arm Tooling. 714,852 saved Models. Millibar Manual Tool Changer.

the lower cost 3D printing machines available. Profile Manifold.

End-of-Arm-Tooling · Millibar Robotics

3D printed EOAT doesn’t need to be adjusted, and internally printed air lines provide a single connection for vacuum and a single connection for pressure instead of having to route external air lines.

End-of-Arm Tooling (EOAT) and 3D Printing

3D Printed End-of-Arm Tooling Components

Click to find the best Results for fanuc end of arm tooling Models for your 3D Printer. Examples? We produce and develop grippers and vacuum tools that work lighter, faster and better. This technology empowers businesses to innovate, adapt, and optimize manufacturing processes. The EOAT gives a robot a specific functionality and can be changed to fit . Since the gripper’s parts were printed exactly as envisioned, assembly and operation are simple to execute. 1-25 fully finished 3D Printed EOAT components in as little as 24 hours, fully built tools in as little as 1 week. End of Arm Tooling, Inc.Our portfolio is rounded off by 3D printing, handling solutions for e-mobility and flexible lightweight composite materials such as FRP, CFRP, GRP or . The volume of material used totals 297.Discover how DLP (digital light processing) 3D printing technology is enabling end-part production at scale with materials, mechanical properties, speed, and part economics similar or better to traditional .In this blog, we’ll delve into the basics of EOAT: how it’s used, design considerations, and the benefits of 3D printing the components. As well as in other areas, we continue to surprise customers in the field of end-of-arm tooling with clever constructions.3D Printing for EOAT.In this article we explore how soft tooling 3D printing works and how it can enhance end-of-arm tooling as well as other applications.A3 Marketing Team | 09/19/2017.

Arm Mounted Manifolds. Not only because . We ensure that pick-and-place robots handle more products per hour. Instead of machining, EOATs are 3D .This serves applications in almost all industries, but for automation and end of arm tooling, 3D printing specifically helps you get specific parts you need – when you need them! The 3D printer extrudes its material and builds the part or tool from the bottom up. They will work with you on a degating test, vacuum cup recommendation, cobot kit demo, 3D printed fingers or your next multi-EOAT project set. Selective Laser Sintering (SLS) This .Real-World Applications: The applications of 3D printed end-of-arm tooling are vast and diverse. Get the best part by choosing the right 3D printing method. Fax: (734) 542-6831. We have a variety of capabilities for printing the best end of arm tooling components for you. >ASS End of Arm Tooling, Inc. Light tools allow the arm to move faster and more efficiently, and conformal . Download our full catalog of end of arm tooling components for easy reference, or order a physical copy. By integrating 3D printing into the production of these components, companies can unlock a new level of customization, agility, and cost-effectiveness. As manufacturing continues to .Even that is possible with 3D printing.End of Arm Tooling, Tool Manufacturing, 3D Printing, Automation Components, and De-Gating Stations Locations Primary 1324 Goldsmith Ave . We’ll also showcase five real-world .End-of-Arm-Tooling (EOAT) – auch als Endeffektoren bezeichnet – bezieht sich auf die Geräte und Anbauteile, die am Ende von Roboterarmen oder Manipulatoren montiert . End-of-arm tooling (EOAT)—the ‘hands’ at the end of industrial robot arms that enable industrial automation – should be lightweight, conformal to each unique part a robot manipulates, and strong enough to move heavy parts. Automation Systems.

End-of-Arm-Tooling (EOAT) End Effectors with FDM 3D Printing

Schnelle, hochpräzise Prototypenfertigung, effiziente Herstellung hochkomplexer Teile, .Andere Inhalte aus markforged.

3D Printing End-of-Arm Tooling. 3D printing has revolutionized the manufacturing industry by providing an efficient and cost . We’ll also showcase five real-world examples of 3D printed EOAT that underscore its value. Industries such as automotive automation systems, electronics assembly, food processing, and e-commerce distribution centres have already embraced this technology.Robotic end-of-arm tooling stands as an essential component in industrial automation, revolutionizing how materials are handled, assembled, and . 3D printing allows for a faster and less expensive EOAT to replace conventionally fabricated tools.

Additive Manufacturing & 3D Printing Solutions

End-of-Arm-Tooling (EOAT) is a crucial element of robotic technology, which broadly refers to the equipment which interacts with the parts or components, typically on the end of a robotic manipulator or arm. Unlike many 3D printing plastics, Markforged’s chopped carbon fiber reinforced nylon . The process can take anywhere from a few hours to a full day.End of arm tooling for robots and other items that assist automation are an important application. ISO 9001 Certificate; Code of Conduct; Official Legal Statement; . 3D Printed end of arm tooling components can be built to achieve an accuracy of +/-. E-mobility, 3D printing, FRP solutions Automotive Lightweight Construction.Headquartered in Michigan, >ASSASS< End of Arm Tooling makes automation easier. See our full range of EOAT components!Interested in learning more about our 3D printing services? We’d love to hear from you.3D printed end-of-arm tooling is strong but light, highly conformal and can be rapidly iterated for a fraction of the cost of traditional tooling.Mechatronic components, gripping solutions and automation for your tasks. With its unparalleled customisation, reduced production costs, .The ability to create customised end-of-arm tooling for . 10000+ fanuc end of arm tooling printable 3D Models.Print custom end-of-arm tooling in a matter of hours to meet changing manufacturing needs.End-of-Arm Tooling (EOAT) is a term for the attachments at the end of robotic arms.3D-Druck bietet intelligentes End-of-Arm-Tooling, das sich durch Einfachheit, Funktionalität und Effizienz auszeichnet. With Markforged’s continuous fiber technology, these parts can withstand thousands of cycles without failing. Toolmaker and injection molder Zero Tolerance developed a manual tool to .

3D Printed End Effectors. This approach . Suction Cup Mount. Tooling Savage Automation Delivers 3D Printed Commercial Manufacturing Aids The company’s approach to designing end-of-arm tooling and other devices has evolved over the years to support longevity . End of Arm Tooling can made with lightweight . We think you’ll find EMI’s 3D .Robotic End-of-Arm Tools and 3D Printing Go Hand in Hand Through the integration of FDM technology, Genesis Systems Group is able to produce tailor made parts at a faster rate. Customer-focused Engineering lets talk EOAT! Design assistance is meant to suggest a From compact workstations and production cells to fully automated turnkey solutions. Blog; Downloads .The ASS Robot Hand Kit (EOAT) as the basis for designing and mounting your end-of-arm-tooling consists of over 2,000 standardized mechatronic components that are .Bewertungen: 105

Products

EOAT (End of Arm Tooling) is used by manufacturers to manipulate, assemble and transport components. You can buy basic/standardized EOATs ready-made, but for challenging shaped parts or faster work, you can use 3D printing to customize them 3d printing with several types . Savage says that in a one-to-one comparison, 3D-printed nylon 12 EOAT is .If a part is coated in paint or chrome 3D Printed EOAT’s can integrate TPU inserts to prevent scratching the finish.End-of-Arm-Tooling (EOAT) Read more. Dual Gripper Mount .

3D Print End of Arm Tooling for dramatic time and cost savings

End of Arm Tooling

show TOP 100 curated Lists. Traditionally built end-of-arm tools are blocky.This paper investigated the feasibility of using 3D printing processes, specifically material extrusion (MEX) and vat photopolymerization (DLP—Digital Light . As the capabilities of 3D printing continue to expand, we can .

3D Printing

free Downloads. The 3D printer was used to create three-dimensional Figure 1. Custom 3D printed gripper fingers from EMI are ideal for use on EOAT in plastics as well as on collaborative robot grippers. days or weeks it takes with traditional fabrication methods. Material used in 3D printing is specific . Firstly, the off-the-shelf EOAT will be assembled to the end of the robotic arm . Oder wie wir oft gefragt werden: So einfach und .The ASS Robot Hand Kit (EOAT) as the basis for designing and mounting your end-of-arm-tooling consists of over 2,000 standardized mechatronic components that are constantly being expanded and supplemented.Learn more about our custom design and build service for simple and advanced end of arm tooling using custom and 3D printed parts! MENU. With Markforged’s continuous fiber .Bewertungen: 105

End-of-Arm Tooling: The Powerhouse of Robotic Automation

Additive manufacturing provides a way to 3D print these specialized .FDM technology provides a faster, more efficient way to make and modify robotic end-of-arm tools (EOAT), also known as end effectors. Located at the end of a robotic arm, EOAT essentially acts as the .The revolution in producing robotic end effectors saves manufacturers time and money by offering unmatched customization, rapid prototyping, material versatility, and cost-effectiveness. That’s because these tools can be printed in hours vs. Figure2shows a schematic diagram of the pick and place program designed by the user. If you have to account for a 5lb tool instead of a 20lb tool, you can spec out a much smaller robotic arm and easily cut 5 figures from your invoice.

3D Printing End of Arm Tooling and End Effectors

No programming or machining is required.3D printing offers a much more efficient way to create jigs and fixtures, assembly and inspection aids, end-of-arm tooling, machining soft jaws and forming dies.3D Printed Human-Operated End-of-Arm Tooling Promotes Safety and Throughput.3D Printing Methods.End-of-arm tooling refers to the tool or accessory attached to the end of a robot arm.The adoption of 3D printed end of arm tooling represents a paradigm shift in the automation industry. 1324 Goldsmith Plymouth, MI 48170 Toll Free: (734) 542-4398.In this blog, we’ll delve into the basics of EOAT: how it’s used, design considerations, and the benefits of 3D printing the components.

The Role of Robotic End Effectors and 3D Printing in Manufacturing

Jigs and fixtures manufacturing with strong thermoplastics offers . It refers to the equipment that interacts with parts and components, typically at the end of a robotic arm.

FDM 3D Printed End-of-Arm Tooling

End of arm tooling (EOAT) is a crucial aspect of robotic technology.comEffizienzen freisetzen: End-of-Arm-Tooling (EOAT) und 3D-Druck in der . Additive manufacturing techniques, such as 3D printing, are used to produce highly customized and lightweight EOAT components. Instead of machining, EOATs are 3D printed using strong thermoplastic .Experience firsthand how 3D printing end-of-arm tooling components save time and cost optimizing the performance of your workflow, and how cloud-based design is giving .

Finally, 3D printed EOAT is lighter than traditional solutions.Planning from the beginning to 3D print end-of-arm tools can directly impact the overall weight that the robot needs to move. Every Day new 3D Models from all over the World.

- Wechsel von audi a6 c8 auf bmw 530d g31: bmw 530d g31 forum

- Fortnite 17 jähriger wert, fortnite level 17 jähriger

- Firmen und arbeitgeber in bad ischl – firmen bad ischl mitarbeiter

- Gelöst: adapter für sony alpha 7 riii | sony alpha 7 treiber windows 10

- Ausbildung: elektroniker für betriebstechnik 2024 | elektroniker für betriebstechnik ausbildungsvergütung

- Wie kommt man nach silithus ? wow classic: wie komme ich nach silithus