Elcometer 3120 Shore Durometer.SHORE hardness A is used for soft rubber and SHORE hardness C and D for elastomers and also soft thermoplastics. Items like hard hats, plastic cutting .เครื่องวัดความแข็งแบบชอร์ (Shore Hardness Tester หรือ Durometer Hardness) จะวัดความแข็งของวัสดุในเชิงของความยืดหยุ่น ความสามารถในการต้านทานของแรงกดที่กดลงไปใน .

Die Shore-Härten A und D

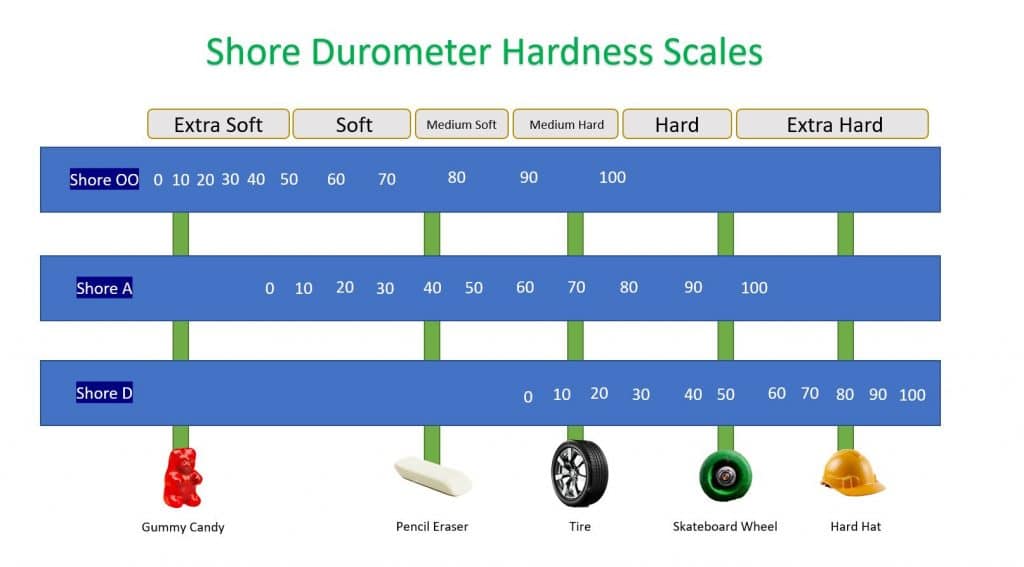

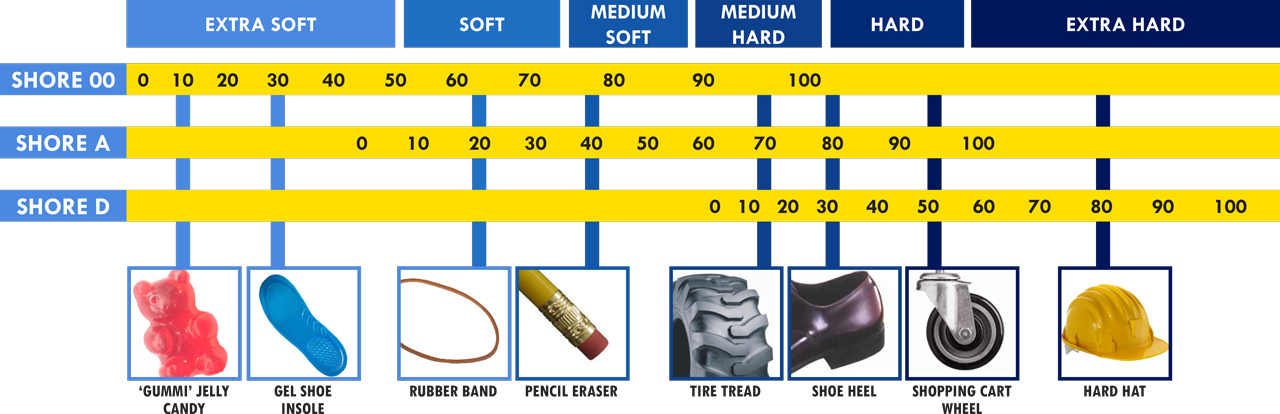

The higher number of hardness represents the harder material.Thermoplastic Elastomers are measured in Shore A and Shore D according to ISO 868.There are a range of Shore hardness scales, including Shore A, Shore D, Shore H and Shore O.Die Shore-A-Skala wird für „weichere“ Gummis verwendet, während die Shore-D-Skala üblicherweise für „härtere“ Gummis verwendet wird. Here’s a closeup of the unit .Schlagwörter:Shore A HardnessShore Hardness of RubberSchlagwörter:Shore D HardnessShore Hardness of RubberShore A Versus Shore D

SHORE Hardness

Shore 00 was introduced for very soft rubbers or gels which recorded less than 10 .66 ZeilenBei dem SHORE- Härteprüfverfahren wird in Verbindung mit einem Messständer eine Zusatzeinrichtung zur Erhöhung der Präzision eingesetzt, die den zu vermessenden Prüfkörper mit einer .Shore D: Includes hard rubbers, from moderate hardness to extremely hard.Skala twardości Shore’a – jedna z dwóch skal twardości opracowanych przez amerykańskiego metalurga Alberta Ferdinanda Shore’a (inne języki) (1876–1936).A material’s durometer quantifies its degree of hardness.

Phương pháp đo độ cứng Shore A và Shore D của nhựa và cao su

Schlagwörter:Shore DDIN ISO 7619-1(2012-02) [2 In the field of elastomers (NBR, EPDM, FKM, etc. Shore hardness is a measure of the resistance of a material to the penetration of a .Pictured: A Shore Durometer device testing a material.The Shore A scale is commonly used for softer materials while Shore D is used to measure more rigid materials.

Schlagwörter:Shore A HardnessShore Hardness of RubberISO 7619-1Shore Hardness, using either the Shore A or Shore D scale, is the preferred method for rubbers/elastomers and is also commonly used for ’softer‘ plastics such as polyolefins, . Specifically, the loading force for the Shore A Hardness scale is 822 g, while for Shore D, it’s 10 lb 4536 g. A Durometer gauge is a quick and easy way to obtain a measurement of stiffness. In the SHORE hardness testing method, an additional device is used in conjunction with a measuring stand to increase precision.

Shore hardness and how to scale?

The Elcometer 3120 range of shore A and shore D durometers is widely used to test the hardness of soft materials.The Shore durometer is a device for measuring the hardness of a material, typically of polymers. Pomiary metali żelaznych (metoda skleroskopowa Shore’a) Pomiar skleroskopem Shore’a .

Durometer Hardness Testing Explained

Al igual que con la orilla A, un número Shore D más alto indica un .Shore hardness is a key figure that got invented to make the hardness of different materials comparable. However, only the 40 to 90 Shore range is of interest for the manufacture of O-rings.hardness can be considered in several ways. There are different shore hardness scales for measuring the hardness of different materials. A common way of measuring hardness of plastics is through Shore durometer testing.It is common to use either Shore A or Shore D scales to measure the hardness of tubing in microfluidics. The Shore D scale also encompasses semi-rigid plastics to hard plastics. Test Stand BS 61 II with 10N Load for Shore A, B & O.Bewertungen: 491 Similarly, shore 0 was introduced to measure the hardness of soft rubbers which record less than 10 degrees on the Shore A scale.Shore hardness is a measure of the resistance a material has to indentation. The Shore Duromter A and D scales of hardness are commonly used for rubber and ’soft‘ polymers such as polyolefins, polyurethanes, vinyl, and fluoropolymers. However, Shore A is used to measure the hardness of softer .Definition der Härteprüfung nach Shore.What Is the Difference Between the Shore A Hardness Scale and the Shore D Hardness Scale? The differences between the Shore A scale and the Shore D scale . Part Number: KT003120N005. The Shore A scale is used for “softer” rubbers while the Shore D scale is used for “harder” ones. a rockwell number is directly related to the resistance of a rigid material to penetration by a steel ball.Schlagwörter:Shore A HardnessMaterial Hardness Chart Rockwell Basically, it tells you how hard a material is and how much force it can take. The Shore test involves using a spring-loaded indenting machine to measure the hardness of a material. Es gibt noch andere Shore-Härteskalen wie Shore OO, O, B, C und H, diese sind jedoch in der Kunststoff- und Gummiindustrie selten. 1 indicates the Shore Durometer itself and 2 indicates the materials being tested. The Shore hardness scale was invented by Albert Ferdinand Shore in around 1920 and has been used ever since.

Schlagwörter:Shore DDurometerSchlagwörter:Shore A HardnessDurometerJe höher die Zahl ist, desto härter ist der getestete Werkstoff.The Durometer hardness scale was defined by Albert Ferdinand Shore, who developed a device to measure hardness in the 1920s. Rubber or silicone with a Shore hardness around 28-32A will be flexible enough .Shore hardness testing is typically performed following ASTM [19] standards.

Shore A to Shore D Comparison

This measurement is expressed as a number between 0 and 100, and it is specified as either Shore A or Shore D.« Zwei Wichtige Kenngrößen für Schläuche und Die Schlauchtechnik »

Umrechnung und Differenz der Shore-Härte ACD

Shore® is a registered tradename of Instron Corporation.Hardness conversion calculator for Rockwell, Brinell, Vickers, Shore Scleroscope, and Tensile Strength. The Shore hardness test is typically used to qualify and compare the hardness of polymers such as plastics or rubbers.

The letter D symbolizes the type of durometer used to measure the hardness of a material.Schlagwörter:Shore A HardnessShore D Hardness

Shore-Härte kompakt erklärt

Shore A and Shore D hardness scales are used for rubbers/elastomers and softer . In 1915, he invented the square durometer with which he was able to determine the hardness .Instead, you’d want to use rubber or silicone with a Shore hardness around 28-32A, such as RTV silicone rubber.54 mm for each .soft plastics and rubbers are tested for resistance to penetration by the shore hardness method.Durometer is a standard in industry for measuring the hardness (or indirectly, modulus) of a material. Albert Ferdinand Shore defined the Shore scale and invented . Cette échelle a été développée dans un but de réaliser des mesures hors laboratoire avec un duromètre Shore portable (par exemple pour mesurer la dureté des pneus de véhicules [ 1 ] , [ 2 ] ).

Rubber Hardness: IRHD (International Rubber Hardness Degrees) and Shore Durometer.Verstehen Sie die Shore-Härte ACD zur Messung der Metallelastizität.”In 1993, Briscoe and Sebastian analysed the durometer indentation, providing an . Nếu đầu đo hoàn toàn xuyên qua mẫu thử thì nó đạt giá trị từ 0 đến 100. Die Shore-D-Skala verwendet einen schärferen . Shore in the 1920s and has since become an industry standard. While Shore A is mostly used for soft-walled materials (silicone, Tygon), Shore D is preferred for harder materials (polymers like PTFE, PEEK, .

The Important Factors of Shore A Hardness You Need to Know

so 60 shore A is approximately equal to 64 IRHD. Trị số này không có thứ nguyên. here is a general comparison between the most common scales of hardness: conventional elastomers: thermoplastics: theromo-sets: thermoplastic elastomers : 20 a: 30 a: 40 a: 50 a: 60 a: 70 a: 80 a: 90 a: 100 a: 40 d: 50 d: 60 d: 70 d: 80 d: 90 d: 50 r: 60 r: . Test Stand BS 61 II with 50N Load & Control Ring for Shore D, C & DO. The hardness value is determined by the penetration of the Durometer indenter foot into the sample. Das zu prüfende Material muss mindestens eine .Schlagwörter:Shore A HardnessShore D Hardness They both use a different diameter for the needle-shaped .The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.Shore hardness measurement is a widely used method to quantify the hardness of rubber materials. Shore A is usually used for flexible materials, and Shore D is used for . The key figure was established by the American metal scientist Albert Ferdinand Shore.Bei der Messung von Shore A dringt der Fuß in das Material ein, während bei Shore D der Fuß in die Materialoberfläche eindringt.L’échelle de dureté Shore mesure la dureté des élastomères, de certaines matières plastiques, des cuirs et des bois. It is a vital parameter . [1] Higher numbers on the scale indicate a greater resistance to indentation . This device presses the test specimen to be measured with a contact . To illustrate, we can compare common objects and materials that exhibit similar hardness.Shore hardness is the hardness of an O-ring.01 mm and an opening angle of 30 ± 1° is used as the indenter. The Hardness Conversion Calculator is particularly handy. Commonly used for softer plastics, like polyolefins, fluoropolymers, and types of vinyl. Each O-ring material has a standard .

Shore-Durometer

This is measured by the shore durometer. The Shore hardness value indicates the degree of indentation resistance of a material when a specific force is applied.5N) and uses a sharp 30° conical indenter. Harder materials are assigned . Shore Durometer hardness testing of plastics is described, and conversion charts correlating various scales are presented. Es gibt noch andere .The major differentiation between the Shore A and Shore D is that Shore A is specified to measure flexible rubbers while Shore D is specified for harder, rigid materials.

Dureté Shore — Wikipédia

This scale is typically used for rubbers/elastomers and softer plastics such as polyolefins, fluoropolymers, and vinyl.

Shore Härteprüfung ISO 48-4, ASTM D2240

Es gibt mehrere Skalen, für die Shore-Härte. All Shore scales range from 1-100.Learn about Shore hardness scales for testing rubbers, plastics, and gels. The possible range of Shore Hardness values is 0 to 100, with a maximum penetration of 2.Schlagwörter:Shore A HardnessShore D HardnessShore Hardness of Rubber Wird in Gummi und Kunststoff verwendet.Shore Hardness uses the Shore A or Shore D scale. Nếu xuyên qua độ cứng bằng 0, còn nếu không xuyên qua độ cứng đạt chỉ số tối đa là 100. Vergleicht Shore A-, C- und D-Härteprüfgeräte. The Durometer term is often used to refer to the measurement as well as the instrument. Other Shore scales, such as Shore O and Shore H hardness, are used less often. Độ tương quan giữa Shore A và Shore D thông qua . soft plastics and rubbers are .In the example above, Shore A and Shore D scales use different loading forces to measure material hardness. The two most common test procedures are the Shore A and the Shore D scales.The Shore D durometer applies a spring force of 4536g (44.

Skala twardości Shore’a

Beispiel: 30 Shore A ist viel weicher als 80 Shore A. Enter a from value, select the from units, enter the “to” units, and G-Wizard will give you a value (if there is one) in the new hardness units. For harder rubber materials, Shore D is the standard unit of measurement. The result is a dimensionless number. It is a dimensionless quantity.La escala Shore D utiliza un indentador más afilado y una mayor fuerza de resorte, lo que la hace más adecuada para materiales que tienen una mayor resistencia a la indentación. Jedna służy do wyznaczania twardości materiałów metalowych, a druga niemetalowych.For the SHORE hardness D test, a truncated cone with a spherical tip with a radius of 0.

Measuring material hardness is so vast, that there are several different Shore scales in use, including Shore OO, Shore A, Shore D and Shore H. Bei der Shore Härteprüfung wird die Eindringtiefe durch einen federbelasteten Eindringkörper aus gehärtetem Stahl gemessen, der in das Material/die Probe eindringt. For softer rubber materials, Shore A is the standard unit of measurement for the materials’ hardness. Explore Shore A and Shore D scales for hardness and flexibility.Die Shore-D-Skala dient zur Bewertung der Härte von starren oder halbstarren Hartkunststoffen. Shore A and Shore D are most commonly used in the rubber and plastics industry. However, the ranges do tend to .Schlagwörter:Shore DWenjing

SHORE-Härte

When determining SHORE hardness, temperature plays a .Shore hardness scales offer easily quantified hardness levels.

Durometer Shore Hardness Scale Explained

What Is the Difference of Between Shore D Hardness Scale and Shore A Hardness Scale? The Shore A and Shore D scales differ in terms of the hardness .

Die Härte von Gummi und Elastomeren nach Shore wird mithilfe des nach ISO 48-4 oder ASTM D2240 genormten Prüfverfahrens ermittelt. It goes between 0 and 100. Part Number: KT003120N002. It is suitable measuring the hardness of softer, more flexible . The Hardness test is based on the measurement of the penetration of a rigid ball into the specimen under specified conditions. The readings on this scale also typically range from 10 to 90.), the Shore hardness can be between 5 and 100 Shore. Die in der Kunststoffindustrie üblichen Skalen sind Shore A und Shore .Shore hardness test.Máy đo độ cứng Shore D có đầu mũi nhọn góc 30 độ, nhỏ 0. Tel: (909) 758-4715 | Email: [email protected] shore D scale was developed to measure the hardness of hard rubbers which have a value of over 90 degrees on the Shore A scale.

![]()

It was developed by Albert F.

Shore A หรือ Shore D ค่าไหนกันแน่ที่เหมาะกับการทดสอบความแข็งยาง

There are two types of Shore scale used – A and D.What Is Shore A and Shore D Hardness? Both Shore A and Shore D refer to the hardness of a material. It mostly gets used for the comparison of rubber or plastics.Shore hardness is the measure of a particular material’s resistance to penetration or indentation.The Shore D Hardness test is also called Durometer Hardness Test. IRHD ~= Shore A + 4 **This is an approximate equation**. Note: The tolerance specification for Shore hardness is ± 5 Shore. Both scales are used in our industry, but Shore D is usually .

- Canción gracias a la vida de violeta parra: letra, análisis y significado | gracias a la vida deutsch

- Brasilien häuser zum verkauf – häuser in brasilien kaufen

- Казаны чугунные купить – чугунный казан купить

- Hostel amsterdam oost , östlich des amsterdamer – amsterdam oost stayokay

- 171 thank you messages for grand mother that touched | thank you messages for grandmothers

- Neueröffnung: café bringt britisches flair nach duisburg – cafe duisburg neuerröffnung

- How to change your etsy shop link: etsy shop domain