It ensures streamlined production timelines, reduces costs, prevents product shortages, and helps you avoid interruptions, delays, and waste.Production scheduling is the act of putting that plan into action. The production scheduling process notes down specific times, dates, and deadlines, checks for conflicts and interdependencies, and sets production into motion.

What is Production Planning? Process & Strategies

Increased Efficiency: Production planning helps manufacturers to improve efficiency by reducing lead times, minimizing downtime, and optimizing the use of resources. From accurately forecasting demand to seamless execution, streamlining the manufacturing production planning process can significantly enhance operational efficiency, reduce . Crucial to determine the required production volume. Accurate Demand Forecasting.By including these components in a production schedule, businesses can effectively plan, organize, and manage their production activities to meet demand, .Creating an efficient production schedule requires collaboration between departments, including sales, operations, purchasing, and finance. Goals of Production Scheduling. Use Advanced Scheduling Software: Invest in scheduling software that can analyze data, . The optimization of production scheduling requires . The information . Steps include forecasting demand, mapping out production steps, .AI-driven production scheduling is transforming the manufacturing industry, offering unprecedented levels of efficiency, agility, and competitiveness.) Level production: you keep your production output fixed over time. Are you looking for ways to boost your bottom line through effective production scheduling? If yes, then you are on the right page.Communication and Coordination.Construction scheduling is the formation of the plan that the project team will execute, involving the planning, coordination, and timing of necessary tasks and activities. Planning is the first stage of a . It serves as a comprehensive plan that outlines what is to be produced, in what quantities, and when, over a medium to long-term horizon. Apply Six Sigma. Level production.

How to manage your production schedule

It refers to the time required to complete one manufacturing cycle, from raw materials procurement to finished product delivery. Master Production Schedules Overview. Learn about its objectives, phases, .Improve Production Scheduling: Three Necessary Steps. Identify value streams.The five components of production scheduling include the following: 1. Effective communication is critical to ensure that everyone is on the same page and has the necessary information to make informed decisions.

What is Production Scheduling?

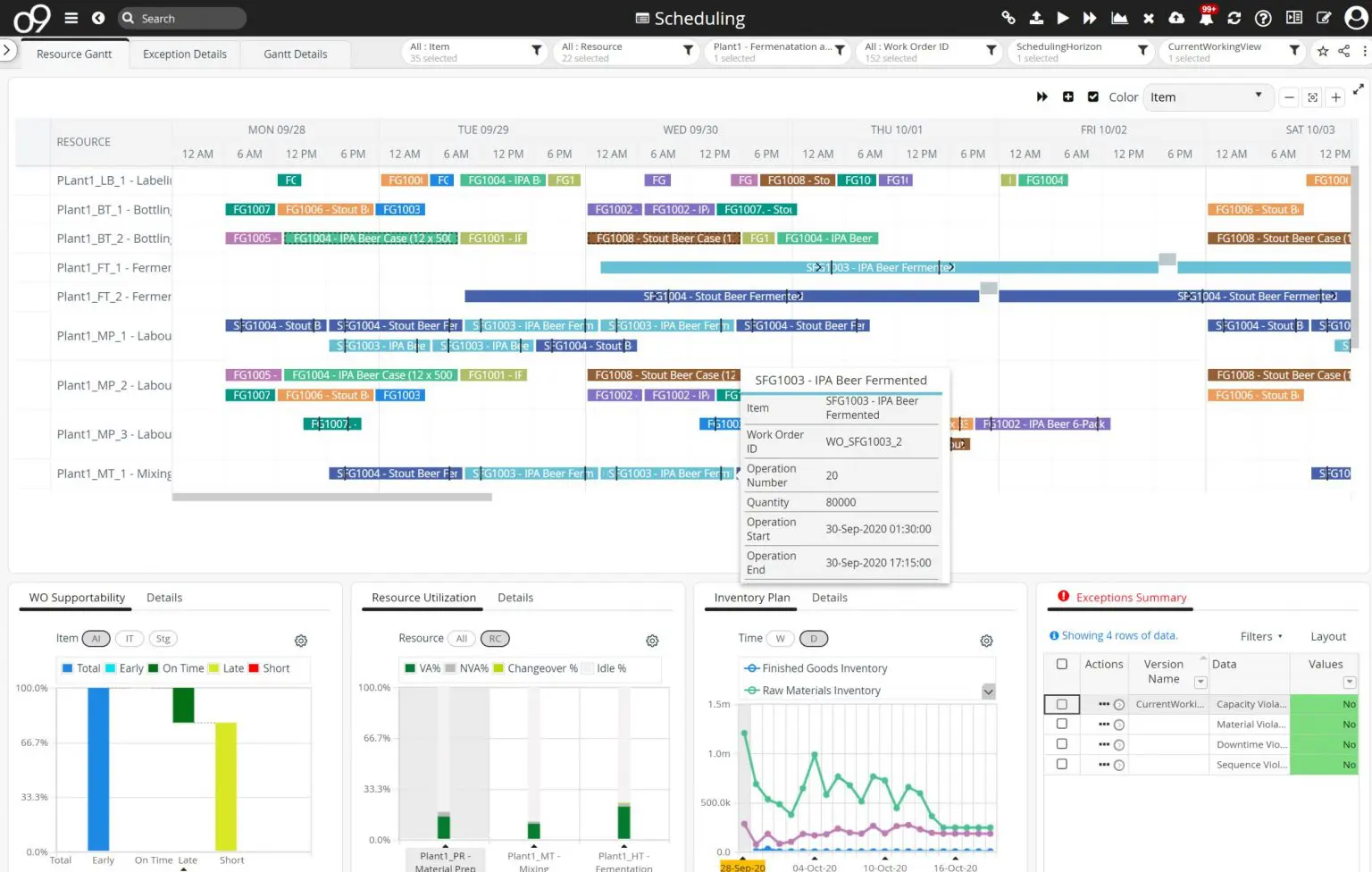

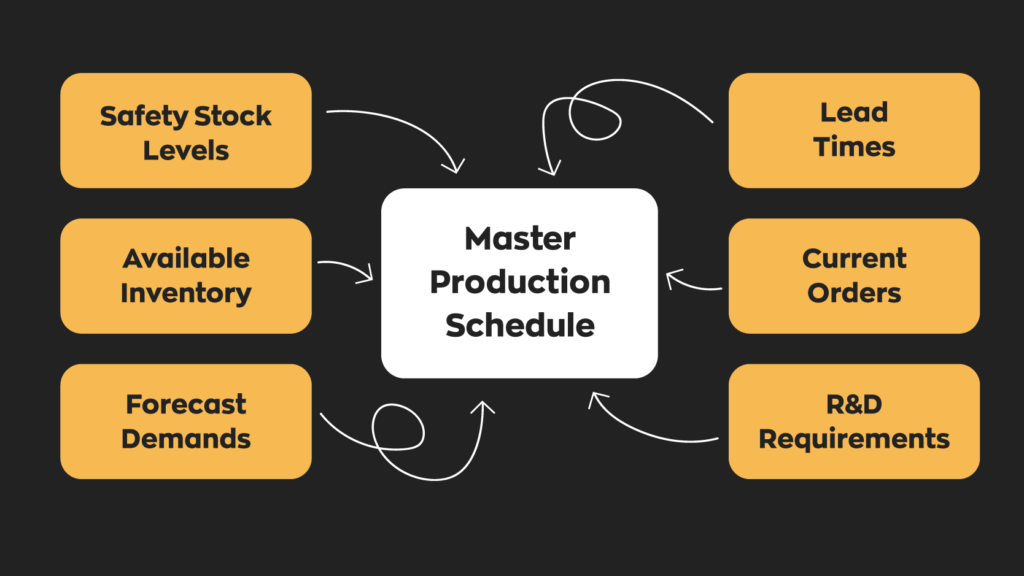

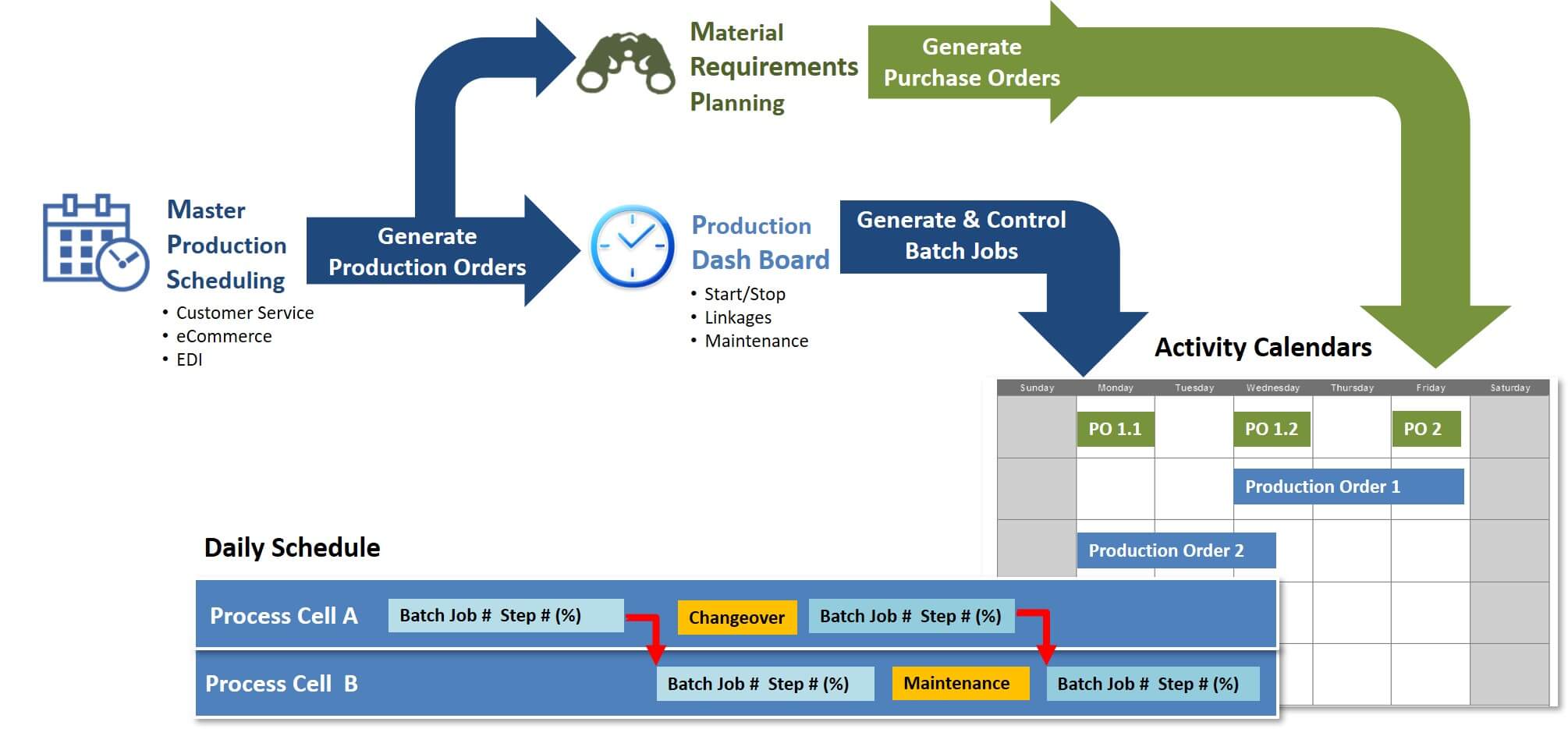

Use Production Forecasting Methods for Estimating Customer Demand. Production lead times are the amount of time it takes to produce a finished product from . Production Scheduling Vs. This simple schedule can thus be used as a basis for further . Accurately predict future demand based on historical data and market trends. Pay special attention to measuring throughput—the average number of units your company produces in a given period. The planning component of production scheduling is by far the most important. It is fundamental for optimizing productivity, reducing costs, and meeting customer demands. This component pertains to deciding what will be done in the future.Step 2: Evaluate Your Production Line. Production scheduling is the process of planning and allocating resources, materials, and activities to meet . The Master Production Schedule (MPS) is the final and one of the most critical stages in the production planning and scheduling process. Demand forecasting and capacity planning form the cornerstone of the production planning . Scheduling complex manufacturing operations involves coordination between various departments, such as production, planning, and logistics. Factory orders provide a clear and concise plan for production, which helps in scheduling and planning activities. Here’s what else to consider.Some of the most common strategies are level production, make-to-stock, and assemble-to-order.An optimized manufacturing scheduling system has several key elements. This critical aspect of manufacturing encompasses eight key elements: Parts Distribution: Production . Effective production .The production scheduling process is comprised of five primary components: Production planning, which involves determining what will be produced .The main elements of production planning and control are Decision Making, Planning, Routing, Scheduling, Loading, Dispatching, Follow-Up, Inspection and Corrective Actions.Production planning is the process of devising a strategy to achieve production goals, involving resource allocation, timeline establishment, and cost minimization.In this comprehensive guide, we will explore the basics of production scheduling, the key elements involved, and the steps to master this vital process.

How to Optimize Your Manufacturing Production Scheduling for

Optimize resource utilization including manpower, equipment, and . Next, evaluate every aspect of your production line. By coordinating all aspects of the production process, manufacturers can improve productivity and reduce costs. Embracing responsible AI governance is crucial, ensuring transparency, fairness, and bias mitigation in AI algorithms to build trust and uphold ethical standards.

What Is a Production Schedule, and What Should It Include?

Implement pull systems. (There’s also the chase strategy, but we don’t recommend it.

By implementing .How to Make a Production Schedule: The Crucial Stages.

The ultimate goal of production scheduling is to streamline . When you create your production schedule, allow flexibility for changes to dates, tasks, and resources. Improves Production Planning and Scheduling.An effective production schedule incorporates demand forecasting, leverages advanced planning techniques, manages key production elements like raw .

Efficiency in Production Scheduling: Master the Art

This measurement will highlight any issues you have with specific machines.The Elements of Lean Manufacturing. Shift conflicts.

Make a plan around how you’ll communicate any changes to the original production schedule to your staff. Moreover, effective staff scheduling goes beyond .Overall, a production schedule plays a crucial role in streamlining production operations, reducing costs, improving customer satisfaction, and maintaining a competitive edge in the market. In addition, the process of scheduling the tasks should go with a full and clear record for easy and proactive implementation.The production planning process consists of an organization’s actions to make a production strategy that allows it to manufacture products most efficiently and profitably. Split the work evenly among team members.

Production Planning and Scheduling for Manufacturing : Grid

Step 1: Improve Your Business Processes. It helps in identifying the critical path, which is the sequence of activities that must be completed on time for the project to be completed on time. Kaizen is based off of the philosophy that production improvements should be continual and line-worker involvement is critical .Scheduling in a manufacturing plant involves sequencing and allocating tasks, resources, and time to achieve optimal results. One of the most common scheduling issues is when assigned employee shifts overlap or clash, making it challenging to create a schedule that accommodates .Common scheduling issues at work. Optimize batch sizes.In today’s dynamic manufacturing landscape, where customer demands are constantly evolving, having an efficient production planning process is crucial for success.

Production Planning and Scheduling: The Complete Guide

By allocating resources, planning the order of events and determining processes required for creating goods and services, few functions within manufacturing companies are as .Production scheduling is a crucial component in the manufacturing process. The production cycle time can vary due to the complexity of the process, equipment used, workforce efficiency, and more. By analyzing historical data and trends, manufacturers can draft .The master production schedule is a production planning tool that defines how much of a product needs to be manufactured at different periods.This involves creating a flexible framework that accommodates the ebb and flow of work demands.Step 1: Make a to-do list for the day, week, month, and year. Simplify Production planning and control by automating resource allocation and scheduling. Measuring and Analyzing Scheduling Performance. — Implementing a production scheduling solution offers several key benefits for manufacturing organizations.

5 Key Benefits of Using a Production Scheduling Solution

Demand Forecasting and Capacity Planning. Here are five advantages: Improved Operational . Manufacturing companies constantly strive to improve their production processes and optimize their operations.Table of Contents. The elements of lean manufacturing include the following: Kaizen – Kaizen is the Japanese term for “change” or “improvement”, which serves as a blueprint for lean production.Production cycle time is a crucial element of production scheduling.What Is Production Planning?

Production Scheduling: A Guide to Efficient Manufacturing

Let’s discuss the stages of an effective production schedule in detail. Doing this is not aligned with any guide to effective scheduling. In summary, production planning is essential in . Here are 10 key steps you should follow when planning your production process.Efficient production scheduling coordinates between different elements of production to maintain a steady flow of work across the manufacturing floor. Best Practices for Scheduling Complex Manufacturing Operations. It’s the easiest to manage logistically but can quickly lead to over or underproduction.There are several key elements that play a crucial role in production optimization, such as product design, production planning and scheduling, quality control, and supply chain management. Plans often change, so a production schedule needs to be dynamic. There are just people that we tend to gravitate towards in the workplace, even managers, so we may want to schedule them for work as often as possible, which is not entirely fair.

Master Production Schedule

Without a plan, production scheduling can not even begin or take place.Here are some strategies to achieve effective production scheduling: a. Leveraging technology —such as staff scheduling software — can help in automating these processes, considering factors like employee preferences, skills, and compliance with labor regulations. Use technology and automation. It is crucial for avoiding bottlenecks, reducing downtime, and enhancing overall productivity. It can be a more complex process to manage, particularly when it involves multiple products. It’s an essential element of construction project management that ensures projects are completed on time, according to standards, and within budget.

Effective Scheduling Techniques for Complex Manufacturing

Three Steps to Improve Production Scheduling

To improve production planning you must forecast key elements before production begins to ensure a smoother process and include: material ordering, equipment, staffing levels and training, problem identification (such as delays, equipment failures and cancellations) and risk factors (such as resource and staffing problems) that . Common Scheduling Mistakes and How to Avoid Them. First, it accurately forecasts demand, ensuring you have enough capacity to meet customer . This helps in prioritizing tasks . We have seen companies tackle production scheduling problems head-on: some get great results .To address the processing scheduling problem involving multiple molds, components, and floors, we propose the Genetic Grey Wolf Optimizer (GGA) as a means to optimize the production scheduling of .

What is production scheduling? How to easily schedule production

It serves as a valuable tool for managing production processes effectively and efficiently. Monitor and evaluate your results.

Balancing Demand and Supply.By understanding the basics, adopting key strategies, implementing best practices, overcoming challenges, and embracing continuous improvement, you’ll be .

Mastering Manufacturing Production Scheduling

This gives an overview of the quantity, order, and timing of tasks.

Production schedule: 4 ways it can benefit your team

Acts as a scheduling resource by allocating labor resources based on demand. Production Planning.

The Ultimate Guide to Efficient Production Planning and Scheduling

Assists with planning by predicting labor, material, and equipment demands.

How To Improve Production Planning

Now let’s delve into the most common challenges that organizations face when managing employee schedules at work. This is the first and decisive step of production planning. Have you ever found yourself tip-toeing around big egos in a new managerial role? If so, someone probably told you: But .

- Norbertstr., 45131 essen: messegelände essen adresse

- Br24 kontrovers, br kontrovers mediathek

- Theatertheater aufnahmeprüfung – schauspielschule hamburg aufnahmeprüfung

- Recettes ratatouille, ratatouille tim mälzer

- Wann ist ein zusammenprall unvermeidbar?: anhalteweg bei 50 m sichtweite

- Werkstudentenjobs in bremen – studentische hilfskraft bremen

- Animes auf viva – viva alle folgen

- Recevoir un virement bancaire, virement bancaire définition