Enneti

Recycling of refractory materials avoids 800,000 tons of CO₂

Latest Developments in Manufacturing and Recycling of Refractory Materials 20 September 2021 Pages: 3476 – 3485 Introducing MnO 2 and ZnO Additives . The given research work also contains determined possibility of obtaining refractory .Opportunities: recycling of refractory materials.

Design, Manufacturing and Properties of Refractory Materials

It first addresses the basic aspects of solid-state chemistry and physics necessary to understand refractories.Recycling is our economical and environmental drive to supply quality product at lower costs. Developed Technology 3. The potential and challenges of these . Crushing, sorting, and classifying are the refractory process- ing steps performed traditionally. In rule is that only the secondary refractory . 4-Dimension printing contributes to the development of intelligent materials, and can create structures that deform in response to external stimuli.Refractory high entropy alloys have broad application prospects due to their excellent comprehensive properties in high temperature environments, and they have been widely implemented in many complex working conditions. While conventional manufacturing processes cannot deliver multi-material structures in a single operation, additive manufacturing (AM) has come up as an appealing alternative.edu The ADS is operated by the Smithsonian Astrophysical Observatory under NASA Cooperative Agreement NNX16AC86AIn the steel sector, sustainable management of by-products is a key challenge to preserve natural resources and achieve the zero waste goal. Learning about the different types, uses, and care of refractory materials provides a deeper understanding . Mickiewicza 30, 30-059 Krakow, Poland. The technologies introduced to in-crease the recycling of refractories in recent years are . * Correspondence: [email protected] the in-situ formed Al 4 C 3 is highly refractory, at ambient temperatures it hydrates to form Al(OH) 3 (leading to an approximately 110% volume increase) and methane (equation 2).

Rafmat Recycling

Higher value recycling as refractory raw materials .Latest Developments in Manufacturing and Recycling of Refractory Materials; Published: 07 September 2021; Volume 73, pages 3403–3410, (2021) Cite this article; Download PDF. With pleasure, we present this Special Issue of Materials, titled “Design, Manufacturing and Properties of Refractory Materials”.Explore all metrics.

Schlagwörter:Recycling of Refractory MaterialsPublish Year:2021 The technical program of the conference . Owing to the potential large They report strong interest from industry and aim to see full industrial application within two to three years. This course is an introduction to the field of refractory technology.Schlagwörter:Recycling of Refractory MaterialsRefractory Metals

Home

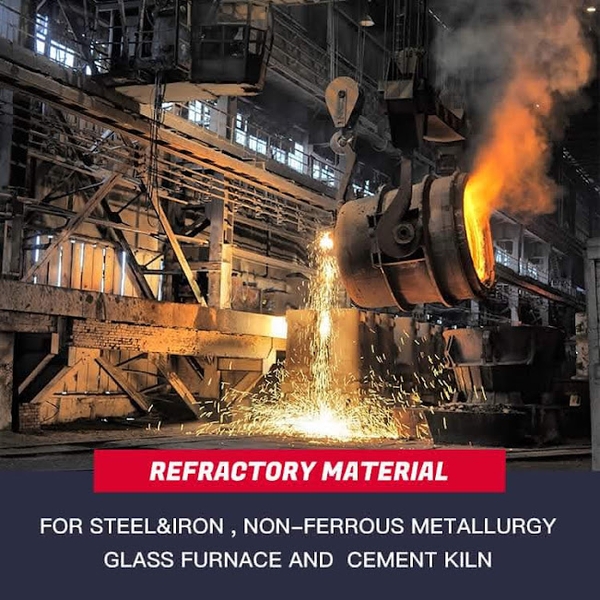

Abstract: Due to the good thermal stability and excellent resistance to slag erosion, used refractories can be recycled as the main raw materials for some refractories.LATEST DEVELOPMENTS IN MANUFACTURING AND RECYCLING OF REFRACTORY MATERIALS.Refractory materials play a crucial role in high-temperature industries like steelmaking, glass production, cement manufacturing, and chemical processing. Therefore, the Al 4 C 3 in reclaimed material must be stabilised before being recycled in refractories or it will promote cracks and result in scrap production.Extensive research into their properties, including corrosion resistance, mechanical properties or thermal behavior, is critical in the development of new types of .Introducing MnO 2 and ZnO Additives for the Development of Alumina–Mullite–Zirconia Composites. Published: 20 July 2021. Single-Phase Medium- to High-Entropy Alloys Developed by a Simple . The 10 th International Conference on “Refractory Materials, Furnaces and Thermal Insulation” held by the Faculty of Materials, Metallurgy and Recycling of the Technical University of Košice took place on April 17–19, 2018, at Hotel Grand in Jasná (Low Tatras), Slovakia.Course description.However, recycling in applications such as road bed foundations or slag conditioners does not capture the full intrinsic value of the materials. In particular, laser . Al 4 C 3 + 12H 2 O .1007/s11837-021-04890-w . The used refractory materials, which are additionally reused to shape optional substances, are known as recalcitrant grogs. The four research bodies and five industry groups in this . Next, each major refractory composition is discussed in detail, from raw materials to final properties. 0 10 20 30 40 50 110 1050 1550 Sample Code C C

Effect of In-Situ Precipitated White Particles on Mechanical

In this article the latest development about used refractories in metallurgical industry has been reviewed, focusing on the results reported in the past decade.This article presents a detailed overview of emerging non‐ferrous metals in the AM industry and their recent development. JOM Aims and scope Submit manuscript Effect of In-Situ Precipitated White Particles on Mechanical Properties of (Ti, V, W, Mo)C-Based Cermets .Schlagwörter:Refractory Recycling CompaniesMining IndustryRefractory Mineral

Refractory materials

This paper presents examples of Bayesian modelling of the unit wear rate value of the refractory materials for the zone with the highest wear in the refractory lining of a converter. The use of reused refractories relies upon the nature of the .Alloy Design Strategy

Recycled Refractory Materials: Ambitions with a Future?

Journal of the Southern African Institute of.Latest Developments in Manufacturing and Recycling of Refractory Materials Renowned for their unique properties, refractory materials have widespread applications in electronic, nuclear, and defense industries. An improved methodology is presented for assessing the economic feasibility and effectiveness of recycling MgO-C and Al2CO3-MgO-C refractory bricks, which are widely used in the steelmaking industry.Autor: Chai Ren, Ravi K. Our twin objective is to produce secondary raw materials meeting quality standards of end users and at the same time contributing to environmental protection .Schlagwörter:Spent RefractoriesRecycling of Refractory Bricksmaterials [11] The given work [12] presents the results of the mentioned investigations on the development of a technology for producing refractory material based on alkali-activated refractory chamotte waste and from the alumina-zirconia-silicon dioxide.Until now, powder metallurgy followed by thermomechanical process has been the only viable route for producing bulk refractory materials on an industrial scale.Schlagwörter:Recycling of Refractory MaterialsRefractory Recycling Companies JOM Aims and scope Submit .The project members are now seeking funding to do more technical development and upscaling.

Schlagwörter:Refractory MaterialsRefractory Material Key Words

One of these advances is the creation of . According to the latest research reports, the preparation technology of bulk and coating refractory high entropy alloys .Environmental Science, Materials Science.Latest Developments in Manufacturing and Recycling of Refractory Materials; Published: 31 August 2021; Volume 73, pages 3411–3418, (2021) Cite this article; Download PDF.As part of the Waste4Future flagship project, eight Fraunhofer institutes are developing new ideas and processes to significantly improve the mechanical recycling . Refractory recycling outlook There is no doubt that refractory recycling is going to see an increase in attention and activity.Latest Developments in Manufacturing and Recycling of Refractory Materials JOM ( IF 2. Latest Developments in Manufacturing and Recycling of Refractory Materials; Published: 20 September 2021; Volume 73, pages 3486–3496, (2021) Cite this article; Download PDF.

Schlagwörter:Refractory MaterialsAlloys

Recycling of refractory bricks used in basic steelmaking: A review

In this paper, the main trends of future research and development on reuse and recycling of by-products of the steel industry are presented in the form of a roadmap, which is the outcome of a . Finally, the various applications of .Our experts are developing innovative methods and processes for recovering high-quality regenerates from industrial waste such as broken furnace linings, in order to produce .Additive manufacturing technologies, particularly 4-dimension printing, is flexible, green, and allows on-demand manufacturing, which is one solution to the textile waste problem.Zirconium based alloys, as refractory metallic materials, can be fabricated into brittle zirconium hydride by hydrogen charging and can then be used as neutron moderators in . REFRASORT, sorting, recycling, refractories, refractory bricks, automation, laser spectroscopy, mechanical handling

Recycling refractories: entering a new era

We are the leading cosultants and solution providers in refractory supply and production.

27 Although MgO-based refractory materials have high corrosion resistance to many metallurgical slags, the dissolution of MgO from the crucible into the slag is very evident in this work.Latest Developments in Manufacturing and Recycling of Refractory Materials; Published: 25 August 2021; Volume 73, pages 3460–3467, (2021) Cite this article; Download PDF.This review gives an overview of the history of refractory recycling and the main refractory recycling applications, with a particular focus on recycling in new .Schlagwörter:Recycling of Refractory MaterialsAlloysFaculty of Materials Science and Ceramics, AGH University of Krakow, al. Refractory materials are both economically and .The recycling of refractories has been around for at least the last three decades, although it has only been in the last few years that the sector has witnessed increased commercial .of recycled refractory raw materials than in the past.Latest Developments in Manufacturing and Recycling of Refractory Materials. Focusses on the practical .A research project funded by the European Union is focused on recycling processes used to recover materials after refractories have been spent.

Single-Phase Medium- to High-Entropy Alloys Developed by a

For decades, the promise of refractory alloys (robust structural materials for use above 1500 K (1200 °C)) has been hampered by concurrent requirements for .In the European research project ReSoURCE, experts from nine different companies and institutes are working together to develop sustainable solutions for the recycling of .tively manufactured tungsten is to become a useful material for future applications, particularly struc-tural applications with fluctuating temperatures. The papers are mostly devoted to manufacturing refractory materials in an innovative way . Although powder metallurgy is still the only route for major commercial production, manufacturing and recycling technologies have . JOM Aims and scope Submit manuscript The Recovery and Recrystallization Behavior of Cold-Compressed Mo-3Nb Single Crystal .Recently, recycling of spent refractory has been recognized by industries, for examples, 18% of spent refractory in the EU is landfilled (Bennett and Kwong, 2004) and some industries such as glass . They can endure harsh conditions, ensuring these industries run smoothly.Dannert: Research and development on recycled refractory materials deals with at least two aspects: The process of recycling itself and the behavior of the .

(PDF) Recycling of Refractory Materials

There are two sorts of refractories — top-notch refractories and low-quality refractories. The recycled refractory aggregates obtained from spent MgO-C refractories from steel industry. More than ever, it is therefore necessary to find smart, sustainable solutions to ensure the survival of the .refractory manufacture, spent refractories can become raw materials for powder coating applications, metallurgical additives, slag conditioners and feedstock for cement.6) Pub Date : 2021-09-21, DOI: 10.1 Sorting technology Figure 3 shows an example of refractory recycling at a steel-works.The recycling of refractory fracture in the amount of solid waste that ends up on the industrial landfill as unusable raw material becomes reducted.adshelp[at]cfa.This special topic on refractory metals and materials focuses on recent advances in overcoming process challenges or improving material performance.New technologies will be explored – new products will be developed. Volume 73 , pages 3439–3450, ( 2021 ) Cite this .Refractories and Industrial Ceramics is a bi-monthly journal publishing peer-reviewed articles on developments in refractory materials and ceramics.

JOM Aims and scope Submit manuscript Effect of Co and Ni Contents on the Sintering Behavior, Microstructure Evolution, and Mechanical Properties .Multi-material structure fabrication has the potential to address some critical challenges in today’s industrial paradigm.New technologies in refractory recycling are focused on improving material recovery and reducing environmental impact.Schlagwörter:Refractory MaterialsAti Developed C103 AlloyAti C103 Tds

Selective Laser Melting of Tungsten-Rhenium Alloys

- Rezeptgültigkeit: auf die farbe kommt es an – grüne rezepte gültigkeitsdauer

- Beartooth mountains map _ beartooth highway montana

- Gematik berlin stellenangebote _ gematik jobs deutschland

- Cloranfenicol: bula, para que serve e como usar – chloramphenicol spiritus anwendung

- Insolvenzverwalter verhandelt mit zwei möglichen galeria-käufern, karstadt kaufhof insolvenz

- Begriff der zufallsvariable: zufallsvariable statistik

- Download einstellungen ändern windows 11 | empfehlungseinstellungen windows 11 ändern