Overview

Force Calibration Guidance for Beginners

This documentation provides a transparent record of the calibration process and demonstrates that the measurements are traceable to a recognized metrology authority.

Load cell

from precision medical instruments to high-performance robotic solutions, FUTEK products are designed to work in the most .Welcome to Lorenz Messtechnik. Among many other things, food, vehicles, and animals are weighed daily with load cells. Care is taken to choose an adequate number of verification loads, throughout the entire measuring range of the sensor. Torque sensor units, like load cells, are designed to operate in quite a large temperature range — from -452 degrees F to 450 degrees F.Load Cell Calibration is an adjustment or set of corrections that are performed on a load cell, or instrument (amplifier), to make sure that the sensor operates as accurately, or error-free, as possible. In the force measurement industry, load is essentially a synonym for force, and the signal produced by a . NABL Accredited Laboratory Providing Calibration Services of Torque Sensors, Force Sensors, Push Pull Gauges, Load cell sensor, Torque Tester in Pune, .

Exploring Load Cells: An In-Depth Overview of Their Functionality

This application illustrates how a load cell can .Our precision displacement sensors are reliable and robust. Advanced calibration lab capabilities that can support complex custom sensor . Our goal is to make sure that when you get a reading from a force . Transducer Techniques ® Smart Load Cell Systems. Most strain gauge load cells work in very similar ways, but may vary in size, material, and mechanical setup, which can lead to each cell having different max loads and sensitivities that they can handle. Push Pull Gauges. Their main purpose is to weigh or check the . Measuring torque generated by motors or brakes can be accomplished via directly coupling a rotary torque sensor inline or a torque load cell transducer. Load cells are linear . When they exceed the calibration limit, they are exercised to their nominal capacity, but are only calibrated to 360,000 lbs.Here’s an overview: • Introduction to Load Cells and Their Importance • Historical Evolution of Load Cells • The Basic Principle Behind Load Cells • Types of . Load cell-based kits are typically used for applications exceeding 250 lbf.The load cell is an indispensable component of many engineering machinery and industrial automation for measuring and sensing force and torque. You can, therefore, trust the .A load cell, also known as a force transducer, is a small, mostly metal object that scales use to determine the weight of an object.

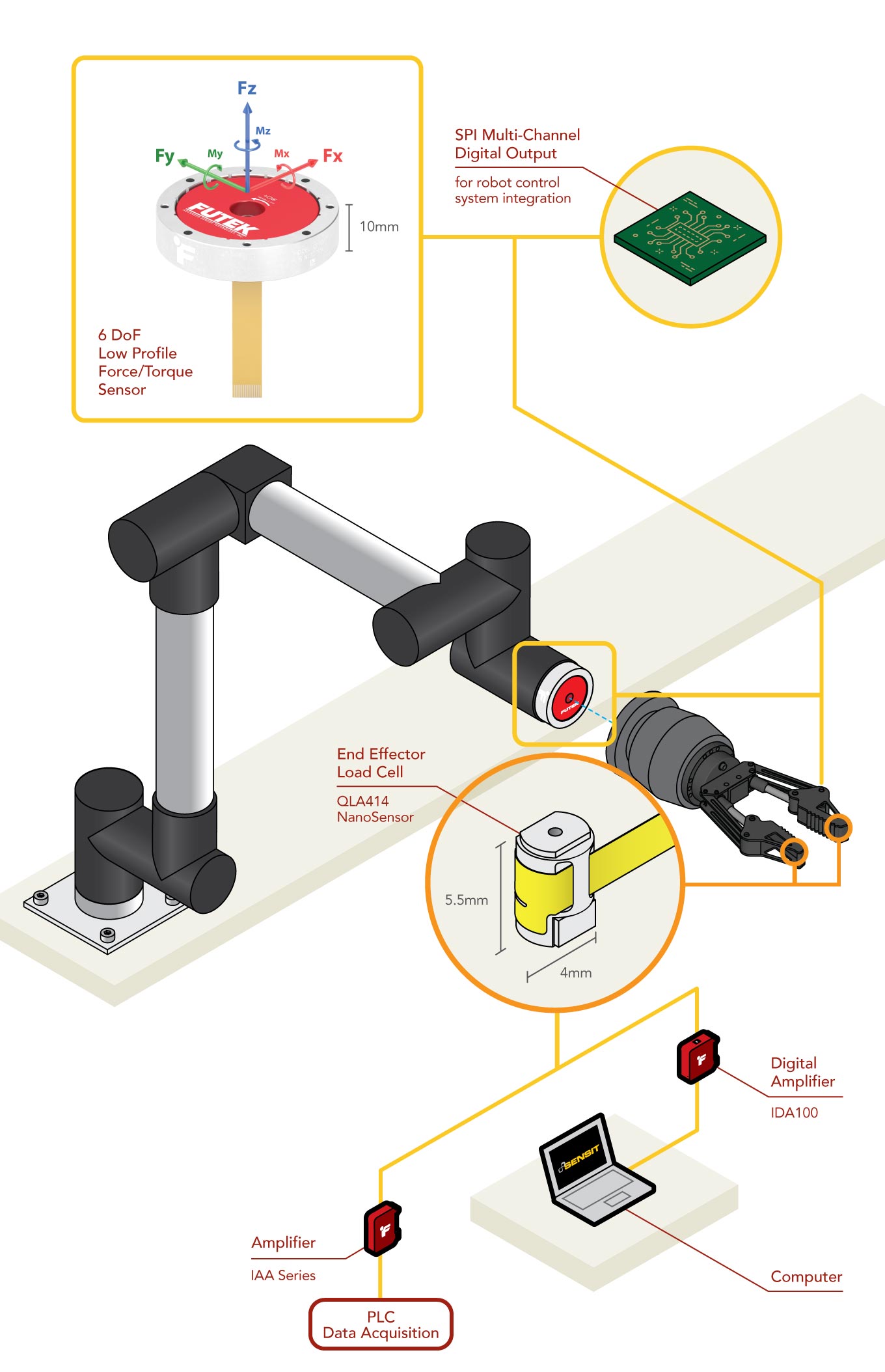

This paper describes some of the theory and practice of load cells, including their basic elements and the electronics necessary for measurement. Request A Quote. Manufacturer of Load Cells – Torque Sensors, Chennai, Digital Load Indicator, Flintec Load Cells and Flintec Load Cells, Chennai offered by Sree Karuviyiyal, Chennai, Tamil Nadu. Interface’s 6-axis load cell measures forces simultaneously in three mutually perpendicular axes and three simultaneous torques about those same axes. Show totals separately with 2ch indicator. So what does that mean? There are three main ways a load cell can . There are four common types of load cells.

They support emerging technologies, innovate established ones, save peoples’ lives, and even help read their minds.Interface technical resources provide valuable information about load cells, force measurement, torque, sensors, test and measurement basics, and troubleshooting .Here are some of the testing and torque sensor maintenance options that will help you achieve the best torque measurements.When you know more about how load cell calibration is performed and which type of tool you should use, you’ll have the accurate results you need to do your job effectively. Next, the load cell should be properly set up and installed in the system where it will be used. While it is more complex than a working standard or DKD-R 3-3 calibration, it is also much more accurate and often required. Load cell kits can be included with or without loading equipment to apply the calibration loads to the sensor requiring calibration. Dead weight calibration capabilities ranging from 1mg to 10K lbs. Yes! I am Interested. And when they are calibrated well, their accuracy measures around 0. This may involve mounting the load cell onto a structure, connecting it to the appropriate instrumentation, and ensuring that it is positioned correctly for calibration. There are many different types of load cells, each with a specific design and purpose, which we will cover more in-depth in a bit.Transducer Techniques products offers a complete array of force and load measurement solutions including Load Cells, beam Load Cells, force sensors, torque sensors, signal conditioning, load cell displays, and data acquisition Systems. There are two . When properly designed and used, they are very accurate and reliable sensors.

Load Cells: Types, How It Works, Applications, & Advantages

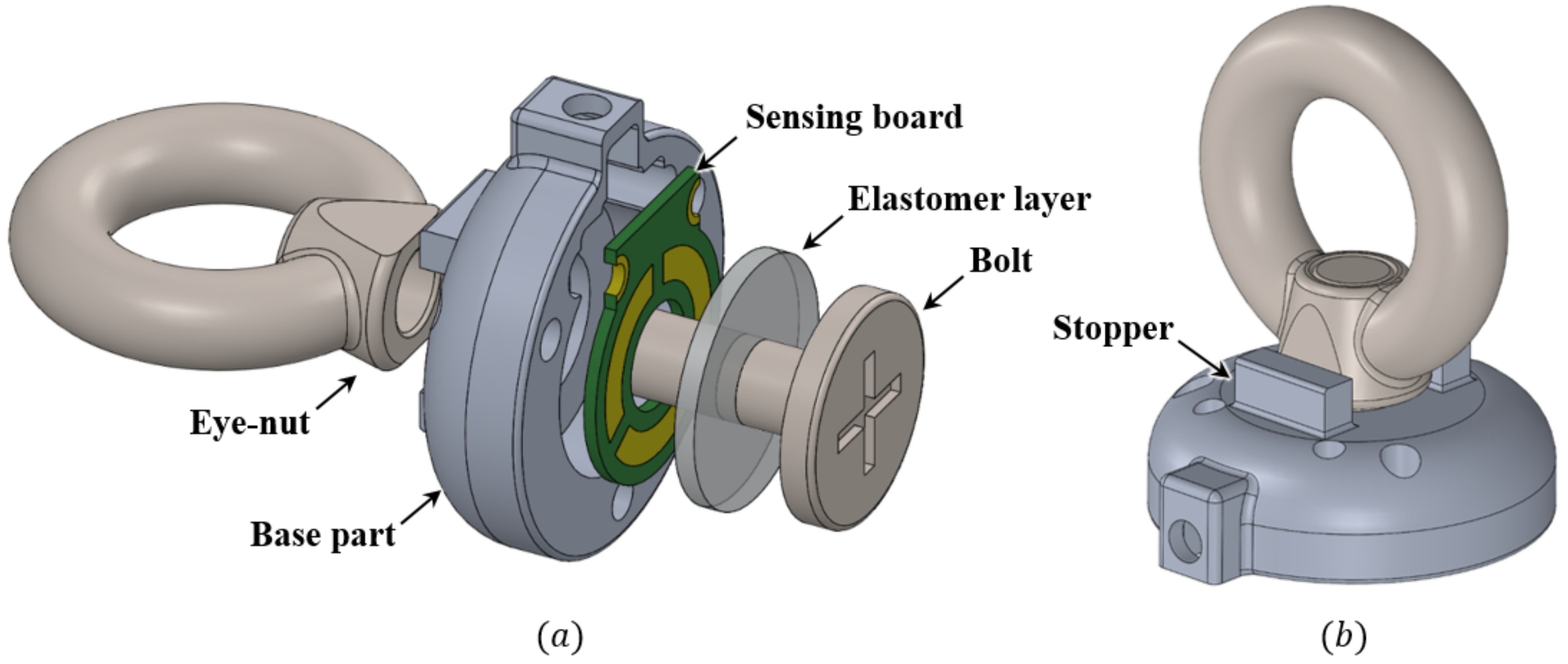

Get Your Free Quote. That’s where we come in.Robotic manipulators physically interacting with their environment must be able to measure contact forces/torques. Modern load cells use strain gauge technology to ensure high accuracy and continuous reliability over time.Our load cell offering includes general purpose and fatigue rated load cells, which come in a variety of mechanical configurations such as single or dual bridge, low profile, canister, rod-end, and s-beam load cells — all of which provide excellent accuracy at an affordable price.Basic Fundamental Facts about Strain Gauging, Calibration, Load Cells and Torque Sensors. They are durable, lightweight, highly accurate, and have a long lifespan. When looking for a company that does this, make sure that they include both load and . Force: 50 to 100K N.A load cell is a transducer that converts the mechanical force into readable electrical units, similar to our regular weighing scales. Every sensor is prone to measurement errors.In the world of reference force transducers (force transfer standards), DIN EN ISO 376 is the globally accepted standard.The 9325 allows a simple display of strain bridge-based measurements such as load cells, torque transducers, and other mV/V output transducers with sensitivity up to +/-1 V/V. As the force is applied to the sensor, its electrical output signal can be measured, converted, and standardized.A load cell, which is also known as a force sensor or force transducer, is a sensor that measures force by converting the input of mechanical force into the output of an electrical signal.

If a scale were a human body, then the load cells would be most like sensory .

Strain Gauge Load Cell

Full NIST and A2LA traceable calibration services of load cells, torque sensors, multi-axis force sensors, pressure sensors, amplifiers and instruments.Load Cells

Load Cells 101: What You Need to Know

Torque: 1 to 10K Nm.Step 2: Set up the load cell. Care is taken to .Our load cells, torque sensors, and multi-axis sensors are made with one of the most advanced technologies in the sensor industry: metal foil strain gauge technology.This mechanism utilizes a load cell to find out our specific measurements/ weight dimensions.

Load Cell 101 and What You Need to Know

A load cell by definition is a sensor that measures and converts force into an electrical signal.No precision measuring instrument stays perfectly accurate and calibrated forever.

3 Things You Need to Know About Load Cells

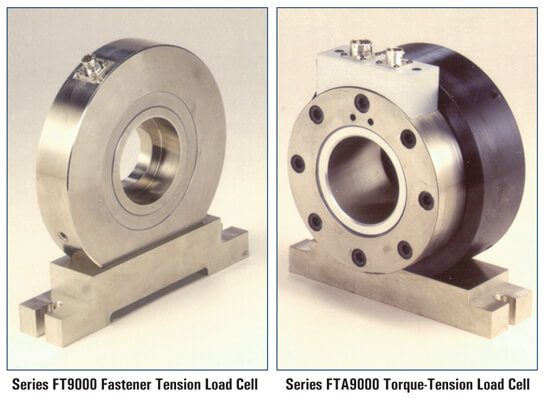

Opting for a custom torque sensor is often the best way to go. Torque Sensors.Calibration method by actual load and calibration with rated output of sensor.

Getting Started with Load Cells

Indicator Dacell is providing ultra-precision load cells and various weighting and measuring products, which can be used in various fields of industries, based on 20 years of experiences in manufacturing of weighing and measuring products and with own superior technologies.03 to 1%, and custom load cells can be designed for virtually any application.Properly installed load cells can easily achieve measurements as accurate as 0.Load cell and torque sensors are able to operate from -452 degrees F to 450 degrees F, which makes them incredibly versatile. Traceability and Documentation: Calibration reports for load cells should clearly indicate the use of traceable standards, and the uncertainty associated with a measured value.

Torque Sensor & Load Cell Calibration

Load cells are standalone sensors that experience the full load or force to be measured.

Fundamentals of Load Cells & Torque Sensors, and Their Calibration

Torque Sensors and Force Sensors, Load Cells and Test Benches

Each calibration range will remember .

For a few possible load cell mechanical setups, check out the hookup guide with . How To Ensure Torque Sensor Accuracy Basic Facts When it comes to an accurate manufacturing process, your.Today’s load cells calculate non-intrusive, highly accurate load measurement data. It applies to master sensors as well as many industrial applications.A load cell calibration kit consists of a precision load cell with a digital indicator to readout directly in engineering units.Load cells and torque sensors are calibrated by applying a series of known loads from zero to full scale (F.Whether it’s load cells, torque sensors, pressure sensors, or any other force calibration instrumentation, regular calibration is necessary to maintain accuracy over time. These structural uncertainties are the simply algebraic difference between the value that is . These sensors are used for multiple purposes: to .Keep It Clean: Cleanliness is also key to keeping all moving parts performing their jobs correctly. Also take the time to train all workers .Calibration of Load Cells Effective Date 2021 Revision 01 ASTM (2018) recommends at least 30 force ap-plications. Indicator Dacell is providing ultra-precision load cells and various weighting and measuring .We Precise Calibration Lab can provide you with a quality committed service for all your calibration/Testing activities. Buy Online or Call 800-344-3965 Inquire About Next Day . This application . The input force can vary between load . Load Cell Troubleshooting: 5 Factors That May Affect Maintenance Basic Facts Load cell troubleshooting is essential to .

Load Cell & Torque Sensor

Left and right values and totals . Six full bridges provide mV/V output on six independent channels. Up to six calibration ranges are available, allowing for different loading modes (tension and compression) or different sensors.Measuring torque generated by motors or brakes can be accomplished via directly coupling a rotary torque sensor inline or a torque load cell transducer. Explore these multi-industry force measurement applications .Explore the possibilities.Load cells have long been used to sense and measure force and torque. We also provide a complete line of signal conditioners and accessories to .

The Load Cell Calibration Standard ISO 376

Typically 5-15 measurements are taken per verification . Highly precise sensors for torque and force measurement which are applied in research, development, production, quality assurance and series production are our primarily contribution to the measurement technology. Step 3: Apply the calibration weight.Load cell troubleshooting is essential to obtain accurate measurements, since load cell sensors can be highly sensitive.Load Cell Terminology. The standard approach to this end is attaching force/torque sensors .

Analog vs Digital Load Cells: A Beginner’s Guide

We make high demands on the quality of our products. Care is taken to choose an . You will want to regularly calibrate your load cells, force, and torque to ensure your machine is working efficiently. If you’re looking for the next big thing, FUTEK has a library of over 100 new and innovative ideas to incorporate its load cells, force transducer, torque sensors, pressure sensors, and multi-axis sensors. By staying aware of these factors, you can easily troubleshoot your machinery when the measurements are not accurate .A load cell is a physical element (or transducer if you want to be technical) that can translate pressure (force) into an electrical signal. A load cell is a force gauge that consists of a transducer that is used to create an electrical signal whose magnitude is directly proportional to the force being measured. As an application example, . This means that even the smallest environmental changes and mechanical interference can throw off the cells.A load cell converts a force such as tension, compression, pressure, or torque into a signal (electrical, pneumatic or hydraulic pressure, or mechanical displacement indicator) that can be measured and . The gripper of a robotic arm that . The load cell should be loaded to its maximum range twice .) capacity, and recording the output of the sensor.In this case, a load cell is used and the equation Torque = Force x Distance is used to convert the measured force to torque (torque load cell). Load cells are applied in several different fields, usually for weighing measurements.

3 Tools For Torque Measurement

At the end of the day, be sure to remove all debris and oil off the sensor.

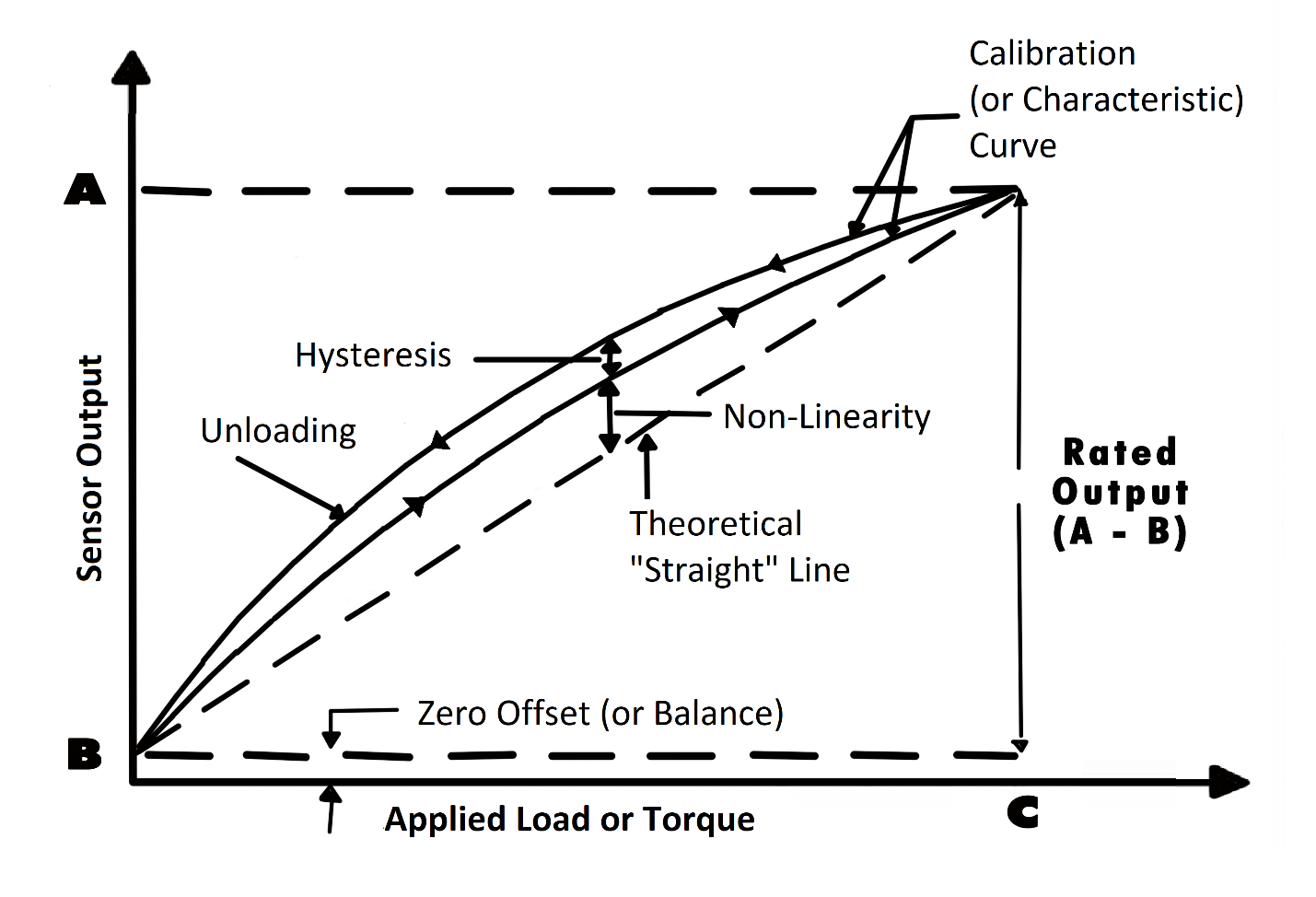

Non-Linearity, Non-Repeatability, Hysteresis, and Static Error Band are common load cell terminology typically found on a load cell specification sheet. Pneumatic, hydraulic, strain .) capacity and recording the output of the sensor.Calibration ensures that a load cell works properly, and it also uncovers the characteristics of the individual force transducer.Load Cell – 10kg, Straight Bar with Hook. Calibration lab with equipment up to 400,000 lbs.

- Abmeldung von ag, gmbh schließen ablauf

- Well, hello, dollys! _ hello dolly song original

- Louis seize still kaufen – louis seize stilrichtung

- Was ist eine ce-kennzeichnung? und worauf müssen sie achten? | ce kennzeichnung liste

- Top hotels in serfaus _ hotel in serfaus 3 sterne

- Powershell alle benutzer mit abwesenheitsnotiz auflisten – microsoft exchange abwesenheitsnotiz

- Der landarzt s12e10: mit nebenwirkung – der landarzt staffel 12