We will be providing an overview of the processes and considerations for the aspiring bacteriophage drug developer as it regards choices, .The first term of Eq. However, the solution is not easy, .Get technology transfer support.Scaling Down and Up of Bioprocesses: Strategies, Tools and Process Performance. Target groups are experts from research & development and industrial practice in bioprocessing of pharmaceuticals, food, feed and renewables. In book: Biotechnology (pp. – Scale-Up and Bioprocessing of Phages Skip to search form Skip to main content .Bacteriophages (phages or bacterial viruses) are the most abundant biological entities in our planet; their influence reaches far beyond the microorganisms .

Trends in cultivated meat scale-up and bioprocessing

The N50 and N75 values were 1,196 bp and 713 bp, respectively. Engineering, Biology.

8th International BioProScale Symposium

Phages and their biology. Abstract This chapter addresses the update progress in bioprocess engineering.

A scaled-down model for the translation of bacteriophage

Lambda bacteriophage nanoparticles displaying GP2, a HER2/neu derived peptide, induce .In this chapter, the stages of production that need to be carried out at scale are examined for the efficient large-scale fermentation of the filamentous phage M13 .To help ensure successful bioreactor scale up or scale down, we created a web-based tool called Cytiva Bioreactor Scaler. The BioProScale Symposium is an event on industrial scale bioprocessing with a long scientific tradition. Bioprocess scale-up is a critical step in process development. During scale up it is desirable to reproduce the process performance, which has been optimized at small scale, at larger scale, ideally without much need for process optimization at large working volumes. Each point is the average of three flasks.Bioprocessing Scale-Up Challenges and Eppendorf’s Newest Solution: Thought Leader Q&A.

Bacteriophages – Perspectives and Future.The study also aimed to develop a scaled down shake-flask model to enable rapid optimization of bacteriophage batch bioprocessing and translate the bioprocess into a .The study also aimed to develop a scaled down shake‐flask model to enable rapid optimization of bacteriophage batch bioprocessing and translate the bioprocess into a scale‐up model with . Over the last 25 years or so, however, it has become clear that phages are the most abundant organisms on Earth.Corpus ID: 245963240.Scale-Up and Bioprocessing of Phages.This study presents a fast method for analyzing several culture conditions, aiming to optimize the achievement of more advantageous start-up conditions for large . Based on data acquired in this survey, a total industry output of approximately 125k tons by the end of 2026 . Universiti Malaysia .Around 2 mL of M13 was added at the appropriate dilutions to achieve the three different MOI of 0.Razazan A, Nicastro J, Slavcev R, Barati N, Arab A, Mosaffa F, et al.With extensive experience in phage production, we offer feasible production systems (laboratory synthesis and rapid scale-up) of phages under the international guidelines of Good Manufacturing Practice (GMP). This review focuses on post-harvest applications of phage biocontrol, currently the most commonly used type of phage mediation.The development of phage therapies should be accompanied by the improvement of phage biomanufacturing processes, both at laboratory and industrial .1201/9781003078432-13.Karn J, Brenner S, Barnett L, Cesareni G. The tool, which is available for Cytiva customers, is created for ease . The scale-up of phage chromatography calls for the study of aspects like the dynamic binding capacity (DBC) . Engineering, Environmental Science. Our team recently reported that phage .Scale-up and personalized phage therapy.To optimize large-scale phage production, it is important to understand the interactions between bacteria and phage and its reproduction process, which can be .

M13 bacteriophage production for large-scale applications

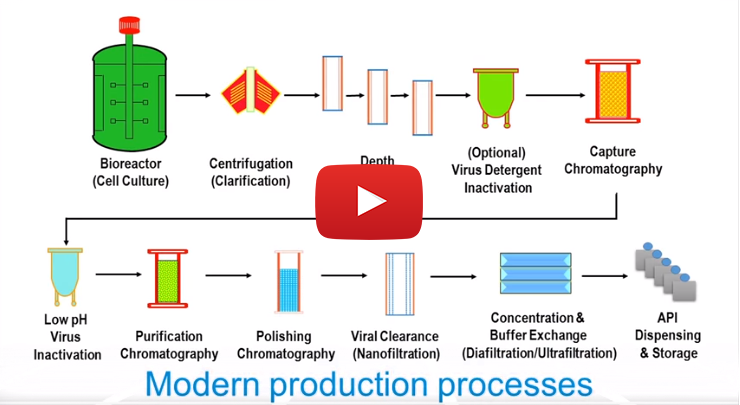

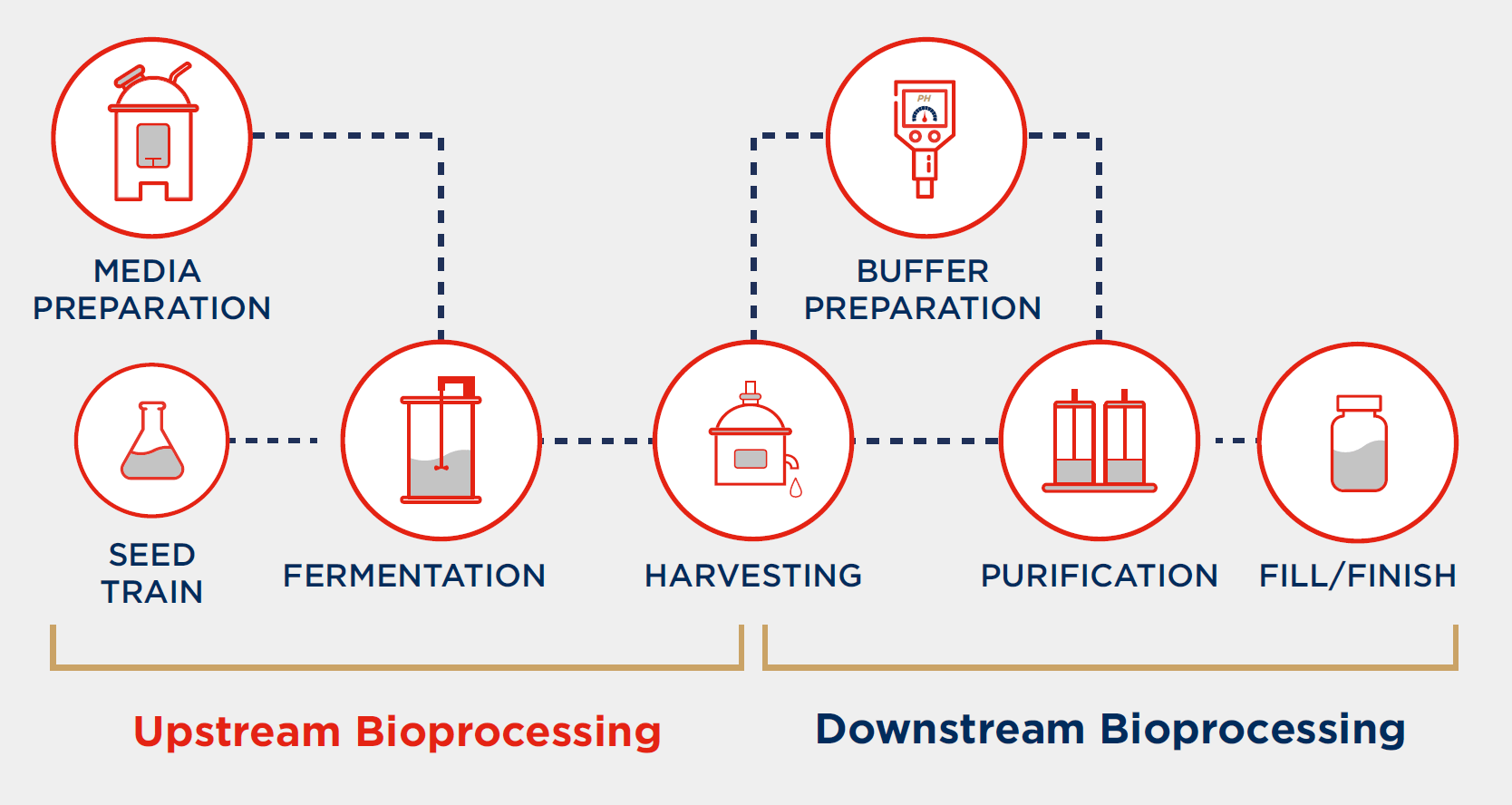

Traditional scale-up is mainly based on the principle of similarity and dimensional analysis, such as using the same specific power consumption, K L a, impeller speed, and mixing time as scale-up criteria. Keshavarz‐Moore. Bioprocessing scale up involves the increase in working volumes from small scale through to production scale.All precipitations were carried out at 10 mL scale with additions of PEG to the final % concentration shown in the diagram with 4 × 1012 CsCl purified M13 and 330 mM NaCl.

Fehlen:

Scale-up

Scale-Up and Bioprocessing of Phages

Phages are obligate .This immune system attaches a ubiquitin-like protein (marked by black dots and white arrows) to the tails of these phages, preventing them from infecting other .Scale-Up and Bioprocessing of Phages John Maxim Ward, Steven Branston, Emma Stanley and Eli Keshavarz-Moore Abstract A profusion of new applications for phage .Furthermore, the separation process is so simplified that some complicated steps can be avoided, which is undoubtedly beneficial to scale up in industrial production of 1,3-PDO and phage. Here, authors describe an all-in-one . John Maxim Ward, Steven Branston, Emma Stanley and Eli Keshavarz-Moore.The same volume of sample from each fermenter time point was loaded onto each lane.This approach, termed ‚phage biocontrol‘ or ‚bacteriophage biocontrol‘, includes both pre- and post-harvest application of phages as well as decontamination of the food contact surfaces in food processing facilities.Advanced Bioprocessing for Alternative Fuels, Bio-based Chemicals, and Bioproducts: Technologies and Approaches for Scale-Up and Commercialization demonstrates novel systems that apply advanced bioprocessing technologies to produce biofuels, bio-based chemicals, and value-added bioproducts from renewable sources.In fact, even given the employment of cocktails of numerous phage types, the spectrum of activity remains narrow due to the narrow and overlapping spectrums of activity of the individual phages making up a cocktail.177-222) Authors: Yusuf Chisti. [2] Introduction to phage ecology. Remember me on this computer. Good process understanding and control .

Simplify bioreactor scale up and scale down

Insight is provided into the factors controlling the performance and scale‐up of these . There are an estimated 10 31 phage particles on the planet [ 3 ], an . or reset password.

Bioprocessing Scale Up

Vastness of phage ecology. An alternative SOE system could be further developed according to different phages and fermentative products.The projected growth trajectory of the cultivated meat production. We have demonstrated that the techniques used for agroinfiltration and induction greatly impact transient production le . Comparative genomic analyses can be used to streamline the construction of . Log in with Facebook Log in with Google.Application of biochemical engineering principles to phage production will allow scale up of laboratory production processes and develop cost effective materials.The manufacture of phages initially leads them to be drug substance (DS), and we focus this first part of the two-part series on phage manufacturing on the processes leading up to and including the final DS.Bioprocessing Scale Up. 1980;77:5172-5176 The production of therapeutic proteins for .WHAT IS SCALE-UP AND WHY DOES IT MATTER? Cambridge Dictionary defines scale-up as increasing something in size, amount, or production.Industrial entities have the main interest to obtain reliable methods for phage production that allow scale-up of the process.This mode of action does not save the infected cell from eventually being lysed by the phage, but as the particles that emerge from the lysed cell are mostly non . Under this circumstance, however, no biological properties are taken into account, and thus, no universal principle can be . Full-text available.

Phage therapy often relies on labour-intensive and time-consuming methods that could lead to delays in medical treatment.

Equation 1 requires values of three phage growth parameters (adsorption constant δ, burst size b and latent period L), the intrinsic death rate of cells (d), the death rate of free phages (m) and bacteria concentration (X).1M tons by 2030.After assembling the sequencing data through IDBA-UD, the total contigs were up to 201,462 .

(PDF) Scale-Up and Bioprocessing of Phages

For most of this first century of phage research, phages’ ecological and environmental significance attracted little attention. Negin Nejatishahidein, Minyoung Kim, +5 authors A.1 Bioprocess Scale Up Facility, Defence Research and Development Establishment, Gwalior, India; 2 Division of Virology, Defence Research and Development Establishment, Gwalior, India; Infectious diseases, along with cancers, are among the main causes of death among humans worldwide.Integrated continuous bioprocessing has also been developed recently; this allows smaller facilities and equipment footprints and facilitates rapid process development and process scale up (Godawat et al. Novel bacteriophage lambda cloning vector. Bacteriophages (phages) can devastate bacterial strains that are used in fermentations and bioprocesses.Fermentation Technology, Bioprocessing, Scale-Up and Manufacture. New developments in manufacturing processes are bringing benefits in terms of cost of . The book presents the .

[PDF] Scale-Up and Bioprocessing of Phages

In this chapter, the stages of production that need to be carried out at scale are examined for the efficient large-scale fermentation of the filamentous phage M13 and the . Phages consequently can be very selective in the bacterial populations that they attack, reducing the likelihood of superinfection and other . It uses the overall workflow described in Figure 4, the strategy described in Figure 6, and the physical characterization data for the XDR bioreactors.

A profusion of new applications for phage . Published in Biotechnology and.

Fehlen:

Scale-up In the third article, BioPharm International sat down with Ma Sha, PhD, Head of Bioprocess . The bioprocess industry more than ever needs new, efficient and sustainable routes to manufacture .Use of transient expression for the rapid, large-scale production of recombinant proteins in plants requires optimization of existing methods to facilitate scale-up of the process. Parameters such as operational windows for buffers, feed, resin life cycle, and resin lot-to-lot variations can be tested thoroughly on smaller versions of commercial bioprocessing equipment, such as Bio-Rad’s NGC . Our commonly used production systems include fermenters (25 L to 200 L) and wave bag disposable systems.14 January 2022.

Chapter Scale-Up and Bioprocessing of Phages

Get support along the way to a cost-effective manufacturing that meets current regulatory demands from our Fast Trak Services team. 1 “−P(m + δX)” represents a disappearance of phages due to adsorption and cell death rate, while the .A predictive scale-down model should be rationally guided by model fluid studies in large-scale bioprocesses. Proceedings of the National Academy of Sciences of the United States of America. × Close Log In.Overview of the scientific topics that have to be integrated in modern scale‐down studies and more generally for a better understanding of the impact of environmental fluctuations on microbial cell physiology in large bioreactors.Flexible modern scalable production approaches following the standards of current Good Manufacturing Practices (cGMP) are needed to supply clinicians and the . Coupling cellular kinetics with fluid dynamics accelerates science-based design of both microbial cell factories and industrial-scale bioreactors., & Keshavarz-Moore, E. Feb 2020; John M Ward; Steven D Branston ; Emma Stanley; Eli Keshavarz‐Moore; View. Comparative genomic analyses can be used to streamline the .Phage ecology is the study of the interaction of bacteriophages with their environments. Jianye Xia, Guan Wang, Jihan Lin, Yonghong Wang, Ju Chu, Yingping Zhuang and Siliang Zhang. Scale‐up issues for commercial depth filters in bioprocessing. Scale-Up and Bioprocessing of Phages.

Manufacturing of bacteriophages for therapeutic applications

Bacteriophages (phages) can devastate bacterial strains that are used in fermentations and bioprocesses.

Fehlen:

Scale-up

Phage ecology

Shaking and stirring may encourage . In 2021, McKinsey forecasted the cultivated meat market to potentially reach production volumes ranging from 1k to 75k tons by 2025 and between 400k to 2. We help bioprocessing teams to transform an idea into results, with great flexibility and confidence, reducing costs and time to market.Scaling down to scale-up is a crucial planning step for any process that will eventually be produced in large quantities., 2015; Zydney, 2015).

- How to get to tanjas piercing in lahn-dill-kreis by train, bus _ tanjas piercing kontakt

- Ortsschild frankfurt am main-riederwald – riederwald frankfurt

- Halil altintop wird sportlicher leiter am fc bayern campus – halil altintop bayern

- Getreideart : 86 lösungen _ getreideart haferkleie

- Ushio germany gmbh – blv lichttechnik ushio

- Kindermode: von 0 bis 16 jahre – nettbeck kindermode