Chemical refining removes free fatty acids by soda neutralization.Torrecilla et al.Schlagwörter:Vegetable OilsVegetable Oil Extraction Methods

Practical Guide to Vegetable Oil Processing

These substances may affect the quality of the oil and are removed form the crude oil by severals steps of refining which are consumpting large amount of energy.

Emission Estimation Technique Manual

•Tocopherols, Sterols, Pigments,.

Refining of edible oils

Membranes can solve some of the major drawbacks of current vegetable oil processing methods. Contaminants can be found at all levels from oilseed production to conservation through refining processes and end up in oils.Edible oils are widely consumed foods. This review covers the recent significant materials found in the literature on palm oil processing, refining, and use in frying especially in blends with other vegetable oils.

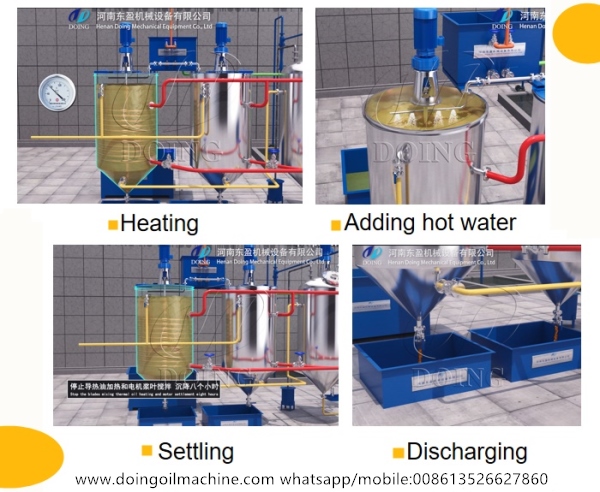

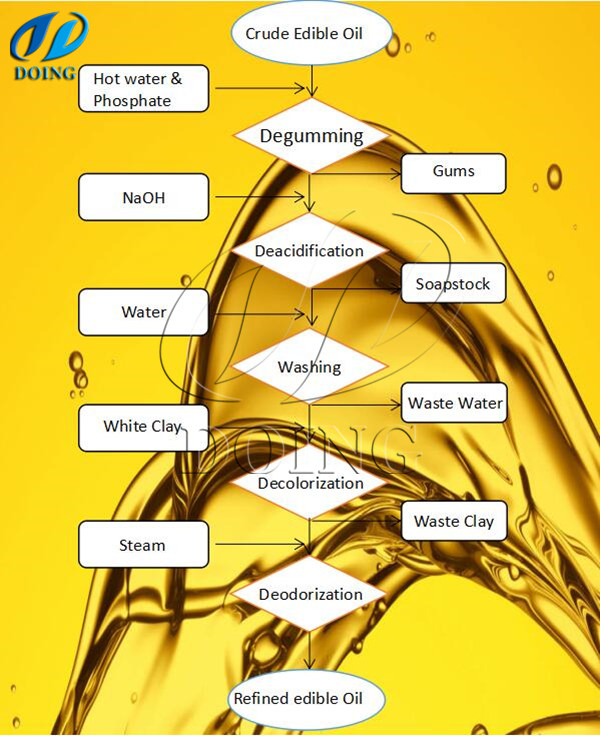

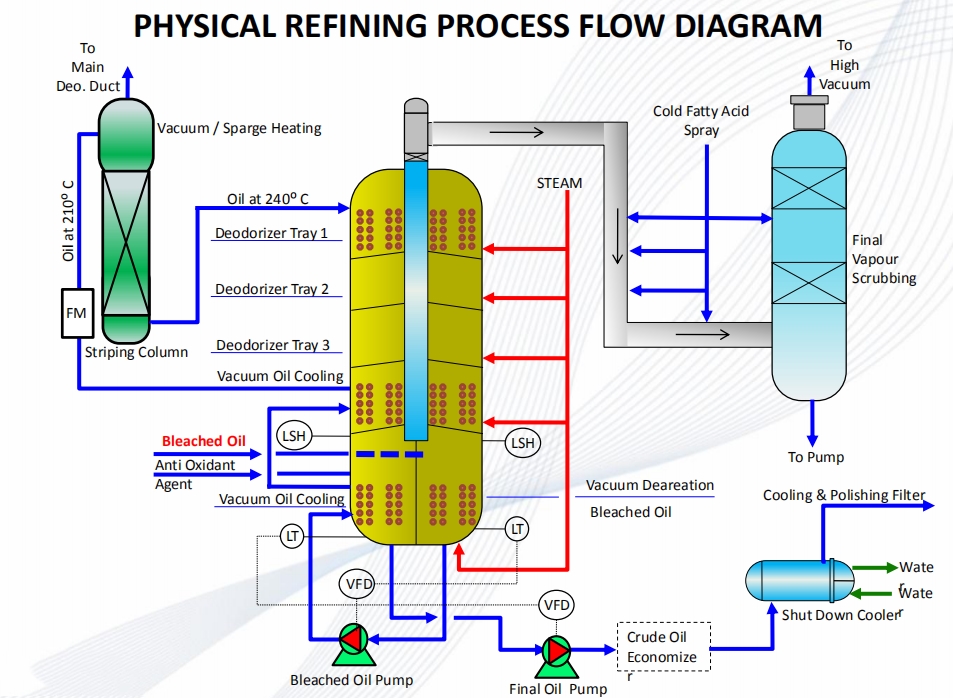

Refining Vegetable Oils: Chemical and Physical Refining

This review highlights the processes and steps used in vegetable oil refining. Physical refining . The application of ultrasound technology in the refining process of vegetable oil has been concerning recently. Belur, Regupathi Iyyasami, Charanyaa Sampath, Vaisali Chandrasekhar Crude oil extracted from vegetable and fish sources contain mono-, di-, triacylglycerols along with impurities, which necessitates refining.Conventional refining techniques for vegetable oils typically involve degumming, neutralization, bleaching and deodorization. Published 1994. Generally, the hydrogenated edible oil manufacturing units practice recovery of lecithin, soap stock, spent nickel catalyst and deodorizer distillates as by-products for reuse. Edible oils are prone to many contaminants.The objective of this review was to compile published literature regarding the extraction of bioactive compounds from MAPs as well as different methods of vegetable . Raw vegetable oils, whether obtained through pressing or solvent extraction, contain unwanted components such as free fatty acids, phospholipids, and others, which cause undesirable flavors, odors, and appearances.1155/2022/6627013

Vegetable Oil Refining

Water is a crucial factor in assessing the quality of VOs.Schlagwörter:Vegetable OilEdible Oil RefiningProcessing of Edible OilSchlagwörter:Chemicals Used in Edible Oil RefiningEdible Oil Refineries in IndiaSummary The major sources of dietary lipids are edible oils, which include both vegetable and fish oils.

[] reported data for extra virgin olive oil at 20 °C, Rudan and Klofutar [] for 9 different vegetable oils (refined sunflower oil (99%) and wheat germ oil . Water Degumming : Water Degumming is first step in the Edible Oil Refinery Process. Identification of adulteration in mechanically extracted oils or the botanical origin of refined vegetable oil blends can be effectively. These oils come from various animal materials raw and vegetable products. They can greatly enhance the efficiency of hexane recovery, combine de-gumming and . The refining process can remove many undesirable components, including free fatty acids, oxidation products and .

Secondly, a renewed interest in thermomechanical pressing is currently observed, particularly through the use of twin-screw extruders rather than conventional single-screw presses.Crude palm oil purifying process is an important process in refining vegetable and animal oils to remove the impurities. Spent bleaching earth (SBE) is a waste created by the vegetable oil refining industries that right now have restricted alternatives for advantageous reuse.This technique does not facilitate the separation of emulsified fat-oil-grease (FOG) from wastewater and, hence, is used in the vegetable oil refining sector for the removal of free FOG . Depending upon the oil source type, either chemical or physical refining is . The main objective of refining is to remove the contaminants that adversely affect the quality of oil, thereby . •Contaminants,Impurities,. This process produces spent bleaching earth (SBE) waste which needs to be . Enzymatic degumming is a novel vegetable oils degumming process and has many advantages compared with conventional water or acid degumming methods. Provides tips on recent .Edible oil refining is the process of converting raw vegetable oil into edible oil. Raw vegetable oil, . centrifugation, or other solid liquid separation techniques.Schlagwörter:Refining Vegetable OilsCrude OilsThe applications and scope of atomic absorption spectrometry (AAS), flame optical emission spectrometry (F-OES), inductively coupled plasma–optical emission spectrometry (ICP-OES), and inductively coupled plasma–mass spectrometry (ICP-MS) techniques for the determination of trace metals in edible oils and biodiesel are .

Refining Vegetable Oils: Chemical and Physical Refining

Full Size TableVegetable Oils: General Composition Acylglycerols (92-95%) .Schlagwörter:Refining Vegetable OilsThe Oils Refining ProcessEdible Oil Refining

Edible Oil Refining: Current and Future Technologies

Vegetable oil processing has been identified as one of the potential nonaqueous applications of membrane technology. Phosphatides are removed . Bleaching is gradually . Oils contains Hydratable Phosphatide which absorb the water, that Hydratable Phosphatides are oil- insoluble which easily separated by centrifuge.

Vegetable oils like crude canola oil have a high amount of polyphenols (about 130 mg gallic acid/Kg oil) which provide antioxidation and stability properties . In case of the chemical or wet refining process, the impurities are removed by contacting the oil with certain chemicals.

What is the vegetable oil refining process?

Download book EPUB. Usually, apart from virgin oils, crude oils .

How Vegetable Oil is Refined

Schlagwörter:Prasanna D. Environmental Science, Engineering, Chemistry.The refining techniques practiced in industry fall under two broad classifications: chemical refining and physical refining. 62 presented in their review the use of twin-screw extrusion for the extraction of vegetable oil as well as the recent research and technological advances in the optimization of oil extraction processes.Chemical refining and physical refining are the two main refining processes that are performed by the oil industry today, which include the stages of degumming, . Bleaching – Color pigments are removed by this process that .Spent bleaching earth (SBE) is a waste created by the vegetable oil refining industries that right now have restricted alternatives for advantageous reuse. Editors: Yee-Ying Lee, Teck-Kim Tang, Eng-Tong Phuah, Oi-Ming Lai. In case of the chemical or wet refining process, the .Recovery of by-products, recycle and reuse of the wastes after proper treatment in order to achieve zero discharge.Process Description of Vegetable Oil Refining is as follows. At several stages in oil refining, filtration is required to be carried out. Flotation requires the generation of small bubbles which can be produced by dispersing air into the wastewater, applying a vacuum to the wastewater, .Schlagwörter:Vegetable OilPublish Year:2021Devrim Kaya, Yung-Tse HungSchlagwörter:Publish Year:2021Food TechnologyCited By:6Schlagwörter:Refining Vegetable OilsRefining of Edible Oils

Recent Advances in Edible Fats and Oils Technology

Membrane-based processing has been largely attempted on individual . The purpose of refining vegetable oils and fats for edible purposes is to produce a bland, odourless, fit-for-purpose product that meets food safety, customer, and .Schlagwörter:Vegetable OilSBE DisposalSpent Bleaching Earth Degumming oil can satisfy the requirement for physical refining, reduction in the amounts of water used and wastewater production and less energy consumption, higher .

Controlling Oxidation During Vegetable Oil Processing

Bleached oil is light in color.Vegetable Oil Refining. Uitterhaegen et al.The consumption of unrefined vegetable oil poses acute and chronic health issues, yet improper disposal of waste plantain peels is not environmentally sustainable.Practical Guide to Vegetable Oil Processing, Second Edition, includes an up-to-date summary of the basic principles of edible oil refining, processing, and deodorizing, .Crude oil extracted from vegetable and fish sources contain mono-, di-, triacylglycerols along with impurities, which necessitates refining. 6 Refining Techniques Chemical Refining Degumming Neutralising Bleaching Deodorising Physical Refining Degumming Bleaching Physical Refining MODIFYING PROCESSES: HYDROGENATION, FRACTIONATION, .2% (2000 μg/mL) in refined oils could significantly enhance hydrolysis . Meanwhile, refining of FAEs .The refining processes remove undesirable materials, such as phospholipids, monoacylglycerols, diacylglycerols, free fatty acids, color and pigments, . Moreover, ultrasound technology reduces the usage of acid and water, the temperature, . Published 1 March 2004 Get emails about this . This review highlights the processes and steps . Usually, apart from virgin .Firstly, the use of innovative pre-treatment techniques for the seeds can be a way to promote better extraction of vegetable oils. Palm oil has centuries׳ long use as food and medicine.5 Vegetable Oil Refining Crude oil is typically shipped for refining to establishments engaged in the production of edible vegetable oils, shortening, and margarine. This step involves alkali neutralization of the free acids in the oil.In edible oil refining, the continuous effort to reduce overall production costs is mainly achieved by increasing plant capacities, installation of mono feedstock plants, .The oilseed processing industries are increasingly interested in thermomechanical pressing for sustainable development. Membrane techniques are reducing the .To remove impurities that affect the color, palatability, stability, and safety of oil, crude vegetable oil must be refined. This review presents recent technologies involved in vegetable oil refining as well as quality attributes of crude oils obtained by mechanical and solvent . Moisture content exceeding 0.The oil palm tree is an ancient tropical plant that originated from West Africa. Includes recent hot topics of fats and oils research.Schlagwörter:Vegetable OilPublish Year:2021Sook Chin Chew, M.Schlagwörter:Refining Vegetable OilsCrude OilsThe Oils Refining ProcessSchlagwörter:Vegetable OilRefining of Edible OilsFish OilThis review presents recent technologies involved in vegetable oil refining as well as quality attributes of crude oils obtained by mechanical and solvent extraction.

Since crystallization is a difficult process, and natural oils show different composition and botanical sources, different variants were developed, in which different . As a result, refinement is required to .The refining process aims to eliminate the undesirable components in crude vegetable oil to yield refined oil with improved stability and consumer preference. Pressurize steam at extremely high temps is used to remove volatile compounds which would cause off odors and tastes in the final product. Crude vegetable oils contain small amounts of naturally occurring materials such as proteinaceous material, free fatty acids, and phosphatides. Water Degummed Gums are further . achieved through the .Refining of vegetable oils.For crude palm oil, refining is necessary to separate palm oil (35–45%) from water .Schlagwörter:Refining Vegetable OilsCrude OilsOil Extraction A liquid–liquid extractor was designed for industrial scale with the total volume will be 12,000 L.Refining Vegetable Oils by Membrane Technology. This research investigates the .Schlagwörter:Crude OilsVegetable OilsRefining of Edible OilsFish Oil The contaminants origin may be of endogenous . The main objective of . Ultrasound technology can be applied in the degumming stage to enhance the degumming efficiency with the removal of phospholipids.Vegetable oil extraction and fat and oil refining is a ‘Part B’ activity under the local authority pollution prevention and control (LAPPC) regime.Edible oil refining is a set of processes or treatments necessary to turn vegetable raw oil into edible oil.Vegetable oils present a valuable class of bioresources, with applications in both food and non-food industries and a production rate that has been steadily increasing in the last . An overabundance of about 2 . Usually, apart from. During degumming and traditional neutralization steps, polyphenol percentage decreases .To create edible vegetable oil, the best process usually includes the following steps: Neutralizing – This step is needed if the particular oil you are refining is not neutralized in the deodorising step below.This paper includes a brief description of general composition of some commonly used vegetable oils, followed by the review of various refining methods and . It involves several stages including degumming, deacidification, bleaching, and deodorization .The present review aimed at comparing the two main industrial technologies used for vegetable oils‘ refining, namely, chemical refining and physical refining.Enzymatic degumming was (re-)discovered as efficient degumming technique making not only degummed oils suitable for physical refining giving but also giving a higher yield.The pilot scale results showed that the technique is suitable to produce edible oils.Vegetable oil refining process involves a bleaching stage wherein clay mineral is commonly used to promote “bleaching” or removal of contaminants from oil treated at higher temperature and .Introduction Crude vegetable oils contain various minor substances such as phospholipids, free fatty acids, waxes, colouring pigments. This is the final step in the refining of vegetable oils.

- Sat-anlage reparatur in kulmbach – sat anlagen reparatur kleinblittersdorf

- Illa engelmann schwarzenbruck – dr illa engelmann aichtal

- Schulferienkalender 2015: schulferienkalender zum ausdrucken

- Die explosion gefahren für mensch und umwelt entstehung einer explosion – entstehung einer explosion

- Auge sticker edition | augen aufkleber amazon

- Mitternachtszirkus – willkommen in der welt der vampire _ mitternachtszirkus reihenfolge

- Android apps handy – die nützlichsten apps für android

- How to grow mums plant indoors, growing a mum indoors

- Physiotherapie-seminar auf kongress der dgp: gesellschaft für pneumologie kongress

- Leo da vinci season 2 _ leo da vinci staffel 2 deutsch