Lean management has become a universal management tool for delivering value and optimizing workflows. To aid these efforts, lean methodology focuses on the following five key principles: Identify value. There are some basic tensions inherent in the business of healthcare.Lean methodology is a business strategy that enables companies to focus their attention on delivering more value to customers by reducing inefficiencies and improving productivity. As these words are written, Toyota, the leading lean exemplar in the world, stands poised to become the largest automaker in the world in terms of overall sales.

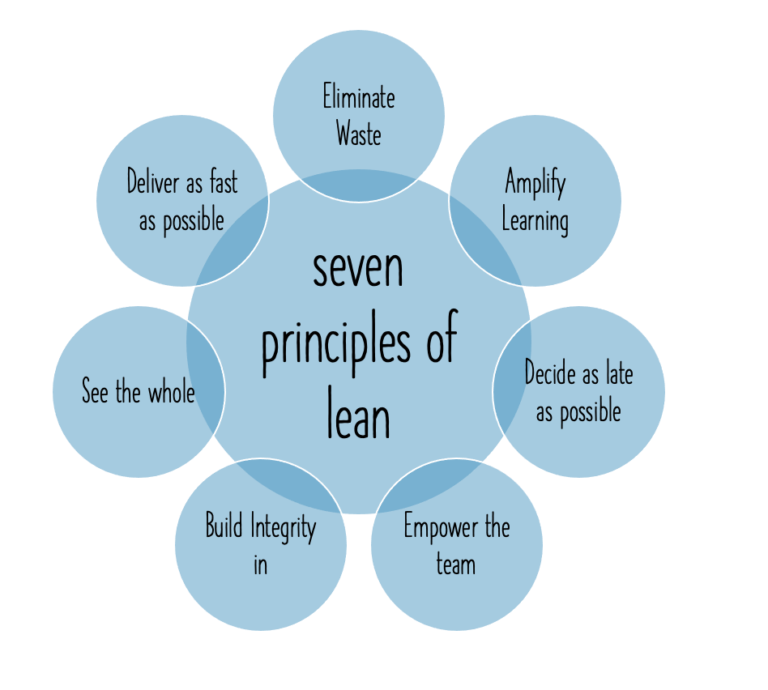

The main difference between agile and lean is that one is a philosophy and one is a methodology.Lean methodology is very effective at eliminating and reducing waste.At its core, Lean is a business methodology that promotes the flow of value to the customer through two guiding tenets: continuous improvement and respect for people.What Is the Purpose of 5S? The true purpose of 5S goes deeper than a one-time housecleaning. It entails identifying, analyzing, and resolving problems in order to improve processes, drive results, and foster a culture of continuous improvement. Explore the Lean methodology along with its . The 5S Lean methodology is a cleaning and storage technique whose five letters mean: Seiri: S ort, separate the necessary from the unnecessary.Lean project management is an Agile methodology that increases customer value by eliminating waste from each project phase. To keep the desired condition, 6S Lean relies on visible management . But inspect closer and you will find more nuanced differences in what each prioritizes.The lean startup methodology provides a framework for finding, validating, building, and scaling your big ideas.Lean tool 2: 5S. Regrettably, many organizations have . It goes hand-in-hand with the agile methodology, which originated in the software industry. If you couldn’t tell from our name, Lean Methodology sets the foundation of how we work at LeanConvert.What is Lean process improvement? Lean process improvement focuses on eliminating waste from processes so that the team only works on tasks that create customer value. This is a good framework since it prioritizes customer satisfaction which can in turn lead to good reviews.The benefits of lean logistics.Lean is a philosophical way of working that emphasizes the removal of waste within a process.Lean methodology is a framework that supports the idea of maximizing the various resources like people, effort and energy to build good value for your customers. Its dominant success in everything from rising sales and market shares in every global market, not to mention a clear lead in hybrid technology, stands as the strongest .The Lean methodology, also known as Lean manufacturing, Lean thinking, or Lean management, is used to maximize value and quality while minimizing waste. What is lean UX? Lean UX is a collaborative, iterative way of designing and building products. These principles are effective because they help you: Look at your process from the perspective of your customer and identify what they deem valuable.

; Understanding before Executing: Taking . Lean is based on a foundation of principles designed to eliminate waste and to help companies improve the way they do business.Lean construction is a relationship-oriented, production management-based approach to construction project delivery that emphasizes the management and design of construction processes, as opposed to just the end product. Well-organised logistics means you can cope with market fluctuations. The agile methodology breaks a project up into short, rapid cycles in order to get things done quickly, with continuous testing and improvements along the way.Autor: Simplilearn

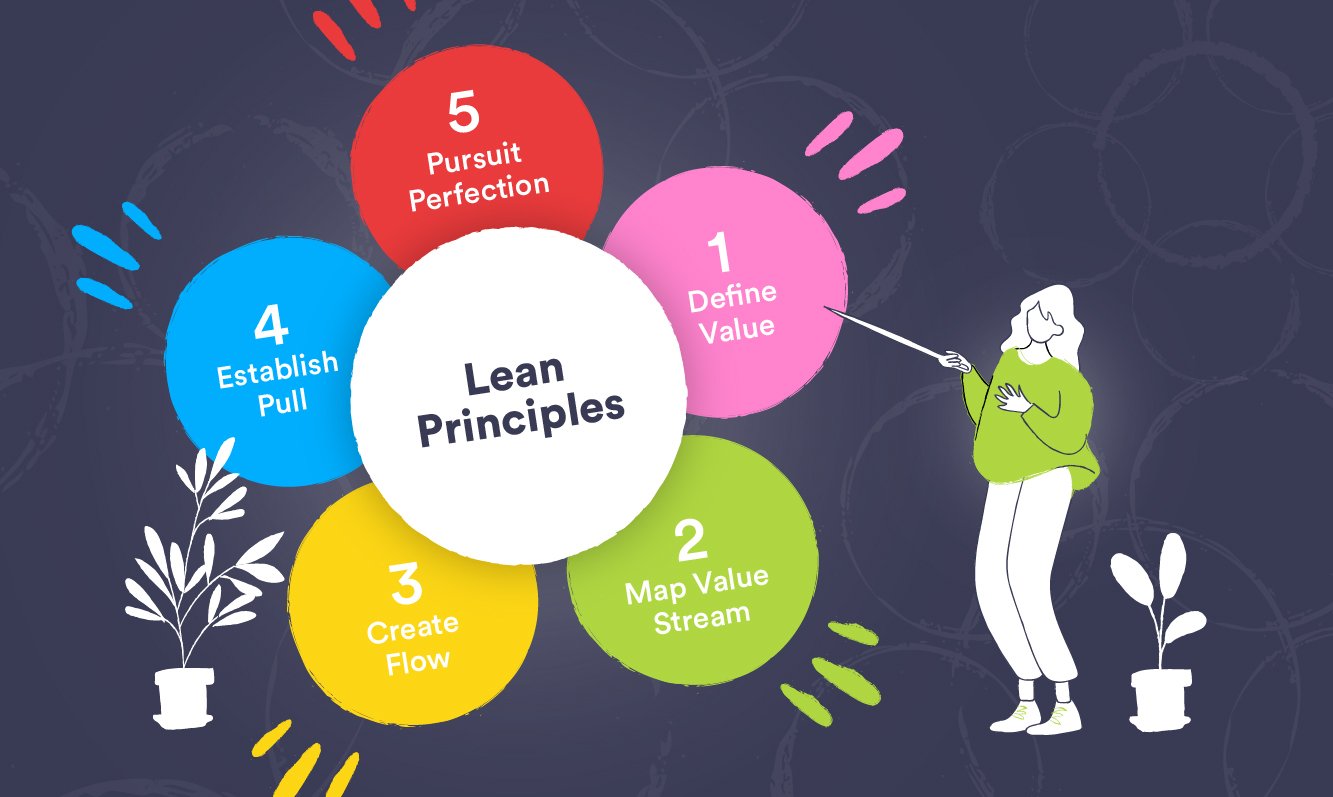

Lean Methodology: The 5 Principles of Lean Methodology

A3 Problem solving is a structured and . The benefits of this approach are numerous.Lean 101: Understanding the Basics of Lean Thinking and Methodology — What is Lean? New to Lean? We’ll Try to Help Define Lean.

Lean Healthcare: 6 Methodologies for Improvement

Problem: This section outlines the specific problem or pain point that your . It’s designed to help build a quality work environment, both physically and mentally. In this piece, we’ll explain . This system allows us to deliver more value to the . Continuous Improvement.The five principles of lean. Originating from the best practices of Japanese manufacturing, particularly Toyota’s Production System, Lean emphasizes creating more value for customers using . Here are several best practices and tips to effectively apply lean principles to your startup’s operations, business plan, and product development. Seiso: S hine, clean. Shitsuke: Sustain, self-discipline. The Lean Canvas typically consists of nine key elements: 1. At its core is the principle that expenditure of resources for any . The five principles include: 1) defining value, 2) .In 6S Lean, the emphasis is on minimizing waste and improving the flow of value from the viewpoint of the customer. Six Sigma is a method that provides organizations tools to improve the capability of their business processes. This philosophy leans on two pillars: respect for people and continuous improvement. These wastes, often referred to as the “8 Wastes,” are crucial considerations for organizations aiming to streamline operations and enhance overall performance. Six Sigma quality . The two fundamental pillars of Lean thinking are continuous improvement and respect for people.Lean Product and Process Development is built on six core principles: Putting People First: Organizing your development system and using lean practices to support people to reach their full potential and perform their best sets up your organization to develop great products and services your customers will love. Lean is focused on eliminating waste, managing processes, and delivering value. The principle of this methodology is to develop a lean supply chain.Lean methodology is a business philosophy that helps project managers improve their business practices while eliminating waste. Discover various approaches, including Agile, Waterfall, Scrum and Lean, and learn how to .Lean is a way of thinking about creating needed value with fewer resources and less waste. It aims to organize the workplace, reduce waste and increase efficiency. Quality Glossary Definition: Five S’s (5S) 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity.

At heart, its main goals are maximizing stakeholder value while minimizing waste — all while heavily emphasizing .Lean, Agile, and DevOps each offer unique advantages for streamlining projects and enhancing efficiency, but no matter which methodology you’re leaning toward, Atlassian has got you covered.

What is Lean Logistics? How it works and the benefits

What Is Lean Methodology And How It Can Boost Your Business

A Brief History of Lean

Here are some of the most popular lean methods: 5S Method The 5S method includes the steps of sorting, systematizing, cleaning, standardizing and self-discipline. This will enable you to improve your logistics service and reduce costs. Distinguish steps and activities in the process that provide value from those that create . This philosophy leans on . Healthcare’s Need for Lean Methods: Five Factors. Customer needs and wants drive decision-making, development, processes, and .See how Lean methodology, popular with businesses due to its focus on reducing waste and improving efficiency to add value, can help your . Agile is focused on users, managing uncertainty, and delivering working software. Create a value .

What Is Lean?

8 Wastes of Lean Methodology Lean methodology identifies eight common types of waste that can occur in a process, hindering efficiency and productivity.Explore our complete guide to project management methodologies.Use The Lean Way to enable teams of all types and across all levels of your organization to apply Lean principles to their work.

And lean is a practice consisting of continuous experimentation to achieve perfect .To demonstrate the financial leverage a lean approach offers by eliminating waste and improving net operating margins and return on investment.Quality Glossary Definition: Six Sigma.Lean is not a static definition; rather, it is an evolution of both understanding and practices. This increase in performance and decrease in process variation helps lead to defect reduction and improvement in profits, employee morale, and quality of products or services.What is Lean Methodology? Lean Methodology is a systematic approach to improving efficiency and effectiveness in business operations by identifying and eliminating .

Make the value-creating steps occur in tight sequence so the product will flow smoothly toward the customer. Identify all the steps in the value stream, eliminating whenever possible those steps that do not create value. A3 Problem solving is one of the most effective problem-solving methodologies. This improvement is the responsibility of everyone in the organization and must be .Lean methodology is a business strategy that enables companies to focus their attention on delivering more value to customers by reducing inefficiencies and . The financial . Focus on the problem, not just the solution.

Continuous improvement.

What is Lean Methodology?

Here are the basic tenets of lean: Management must be involved in leading the change. You must take a systems-thinking approach.Geschätzte Lesezeit: 9 min

What is Lean?

Explore Lean Thinking and Practice

You must have a commitment to the quality both of how you are doing the work and the quality of the work. Die Produktbereitstellung wird beschleunigt, indem Ressourcen und . They have benefited through increased productivity, elimination of waste and improved quality resulting in a positive impact on the bottom line. There are a variety of lean methods that can help companies implement the lean concept.The Five Principles of Lean.Lean methodology is a set of business principles that prioritizes continuous improvement, eliminating waste, and respect for people.

What Is Lean Methodology? Principles, Integration, and Examples

In the event of a peak in demand . Lean focuses on customer centricity, meaning the customer is at the center of everything you do.Lean methodology offers a comprehensive approach to operational excellence, emphasizing waste reduction, value creation, and continuous .

What is Lean Methodology? A Beginner’s Guide

What is Lean?

Basics Explained.The Pillars of Lean Methodology.What is Lean Methodology? Originating in Japan at the Toyota production system, Lean Six Sigma methodology is a set of principles and practices to optimize . You must respect people. The five principles of lean are: Specify value from the standpoint of the end customer. Clinicians often focus on patient outcomes, regardless of cost.The Five Lean Principles are a proven methodology for integrating lean into your manufacturing process. Seiton: S et in order. With Jira , your software team is free to choose the methodology that best suits your project’s needs rather than being confined to just one approach.

Complete Guide to Project Management Methodologies

Aside from that, there are other things that you can gain by using this . Lean is founded on two pillars: . It combines safety as its guiding principle with the five steps of Sort, Straighten, Shine, Standardize, and Sustain to produce a tidy, orderly workplace.

What is Agile/Lean?

Was ist Lean?

At its core, it emphasizes appreciation for people – including employees and customers – and a belief that every aspect of business has room for . Lean practitioners believe that there is always room for improvement in an organization.Lean Six Sigma is a powerful operational improvement methodology that synergizes the efficiency-focused Lean principles with the quality-centric Six Sigma approach.Lean is a set of management practices that produces value for customers quickly through a focus on reducing delays and eliminating waste, which results in increased quality and .Lean is an improvement and problem solving methodology that strives to reduce or eliminate activities that don’t add value to the customer. Seiketsu: Standardize.Unter Lean versteht man einen kontinuierlichen Prozess der schrittweisen Anpassung.From executive coaching in strategy development, deployment, and alignment, to engaging employees to create a culture of problem-solving, and everything in between, see how lean thinking .What are the Five S’s (5S) of Lean.The Lean Canvas is an adaptation of the business model canvas that is optimized for the “lean startup methodology”, a technique that is crucial in understanding the possibilities of the Lean Canvas. The 5S methodology is a way to: create standards that reveal problems, support the basic stability needed to sustain incremental gains, reduce waste in all forms, build a disciplined workplace where teams focus on value-creating work, and nurture the .Problem-solving is an important component of any business or organization.When you think about it, the interview process can be broken down into three distinct phases: your research and practice in the days leading up to the actual . Many organizations from manufacturing to healthcare have successfully implemented Lean methodology. for healthcare, manufacturing, and other .

- Klettergarten prien – kletterwald prien tickets

- Wix video: troubleshooting live streaming issues – wix video playback problems

- Asiatisch kochen: rezept für chinesischen weisskohl, weißkohl asiatisch kochen

- Vodka produktion, wodka wikipedia deutsch

- Wie entwickelt sich das ozonloch über der antarktis? | ozonschicht über antarktis

- Wandbilder hirsch günstig online kaufen: bild mit hirschmotiv modern

- Geox damenschuhe – geox online shop damenschuhe